Renewable-powered auto plants represent a significant leap towards a sustainable future for the automotive industry. These facilities utilize clean energy sources like solar and wind power to fuel manufacturing processes, dramatically reducing their carbon footprint. The design and implementation of these plants involve careful consideration of various factors, including energy efficiency, environmental impact, and economic viability.

This document explores the multifaceted aspects of renewable-powered auto plants, from the technical intricacies of integrating renewable energy sources to the societal and ethical considerations surrounding their implementation. We will examine case studies, analyze future trends, and delve into the regulatory frameworks that will shape their development.

Introduction to Renewable-Powered Auto Plants

Renewable-powered auto plants represent a significant shift towards sustainable manufacturing practices in the automotive industry. These facilities leverage renewable energy sources to reduce their environmental footprint and contribute to a greener future. They are crucial in mitigating the carbon emissions associated with traditional automotive production methods.

Key Components of a Renewable-Powered Auto Plant, Renewable-powered auto plants

These facilities integrate renewable energy systems alongside traditional manufacturing equipment. Essential components include solar panels, wind turbines, or hydroelectric generators, strategically situated to maximize energy capture. Battery storage systems are also critical to ensure a consistent energy supply, even during periods of low renewable energy generation. Furthermore, advanced energy management systems are implemented to optimize energy distribution and usage throughout the plant.

Renewable Energy Sources Employed

The choice of renewable energy source depends on factors like geographical location and available resources. Solar power is prevalent in regions with abundant sunlight, while wind power is often favored in areas with strong consistent winds. Hydropower is another viable option, particularly in regions with suitable water sources. Combined systems, integrating multiple renewable sources, can provide a more resilient and reliable energy supply.

For example, a plant situated near a hydroelectric dam and a region with abundant sunlight might use both solar and hydro power.

Manufacturing Processes in Renewable-Powered Plants

Manufacturing processes in these plants are designed to minimize energy consumption and maximize efficiency. This includes optimized material handling systems, energy-efficient machinery, and waste reduction strategies. For example, robotic systems are often integrated to perform repetitive tasks, reducing human intervention and energy expenditure. Furthermore, the design of the production line itself is optimized for minimizing energy loss during material movement.

Production Process Flowchart

The following flowchart illustrates a simplified production process in a renewable-powered auto plant.

+-----------------+

| Raw Material In |

+-----------------+

|

V

+-----------------+

| Material Prep |

+-----------------+

|

V

+-----------------+

| Component Assembly|

+-----------------+

|

V

+-----------------+

| Quality Control |

+-----------------+

|

V

+-----------------+

| Final Assembly |

+-----------------+

|

V

+-----------------+

| Vehicle Testing |

+-----------------+

|

V

+-----------------+

| Finished Vehicle Out|

+-----------------+

This basic flowchart Artikels the sequential stages involved.

Renewable-powered auto plants are gaining traction, and their potential is huge. This technology is crucial for the future of the automotive industry, and applications extend beyond the typical passenger cars. For instance, the development of renewable-powered auto plants designed for off road vehicles is also a significant area of research, offering innovative solutions for challenging terrains.

The need for sustainable off-road vehicles further strengthens the demand for these advanced renewable-powered auto plants.

Each stage incorporates energy-efficient procedures and technologies to minimize the environmental impact. For instance, automated material handling systems reduce the need for human labor and associated energy consumption.

Environmental Impact Analysis

Renewable energy sources are crucial for mitigating the environmental impact of automotive manufacturing. Transitioning to renewable-powered auto plants significantly reduces reliance on fossil fuels, leading to a substantial decrease in greenhouse gas emissions and air pollution. This shift also paves the way for more sustainable waste management practices.

The adoption of renewable energy in these facilities results in a demonstrable improvement in overall environmental performance. By reducing reliance on traditional energy sources, we see a tangible reduction in the carbon footprint associated with the production process. This is a critical step towards achieving global sustainability goals.

Environmental Benefits of Renewable Energy

The use of renewable energy sources in automotive plants offers substantial environmental advantages. These advantages extend beyond the reduction in carbon emissions, encompassing a spectrum of positive environmental impacts. The use of solar, wind, or hydro power drastically lowers the facility’s carbon footprint, directly contributing to cleaner air and water.

Reduction in Carbon Footprint

Switching from fossil fuels to renewable energy sources demonstrably reduces the carbon footprint of auto plants. This reduction translates into a lower environmental impact, contributing to a healthier planet. For example, a plant powered by solar energy produces zero emissions during operation, significantly reducing its contribution to climate change. Comparing a traditional coal-powered plant to a solar-powered one reveals a dramatic difference in emissions levels.

Waste Reduction and Recycling Potential

Waste reduction and recycling initiatives within renewable-powered auto plants are not just possible, but are often integral to their operation. The focus on sustainability fosters a culture of waste minimization and responsible resource management. Materials can be recycled or repurposed, minimizing landfill waste and resource depletion. This comprehensive approach to waste management showcases the interconnectedness of environmental responsibility and economic viability.

Energy Efficiency Comparison

Renewable energy-powered plants often demonstrate higher energy efficiency compared to conventional ones. This enhanced efficiency reduces the overall energy consumption required for manufacturing, resulting in lower operational costs and a smaller environmental footprint. The use of solar panels, for instance, allows for direct conversion of sunlight into electricity, maximizing energy efficiency and minimizing energy loss.

Environmental Impact Metrics Table

| Renewable Energy Source | CO2 Emissions (kg/kWh) | Water Consumption (liters/kWh) | Land Use (m2/kWh) |

|---|---|---|---|

| Solar Photovoltaic | 0 | 5 | 10 |

| Wind Turbine | 0 | 2 | 20 |

| Hydropower | 0 | 1 | 5 |

| Geothermal | 0 | 0.5 | 15 |

Note: Values are approximate and can vary depending on specific plant design, location, and operating conditions.

Economic Considerations

Establishing renewable-powered auto plants presents both significant upfront investment and potential long-term financial benefits. A thorough analysis of initial costs, projected savings, and available incentives is crucial for assessing the economic viability of these ventures in different regions. Careful consideration of the return on investment (ROI) in comparison to conventional plants is essential for informed decision-making.

Initial Investment Costs

The initial capital expenditure for building a renewable-powered auto plant is substantial. Factors influencing these costs include the scale of the facility, the types of renewable energy sources utilized (solar, wind, hydro), the complexity of the production process, and the specific location. For instance, a large-scale solar-powered plant will likely involve higher upfront costs for land acquisition, solar panel installation, and grid connection infrastructure compared to a smaller-scale wind-powered facility.

These costs are not always uniform, depending on local regulations, material costs, and labor rates.

Projected Long-Term Cost Savings on Energy Bills

Implementing renewable energy sources can substantially reduce long-term energy costs. By leveraging sustainable energy sources, auto plants can significantly decrease their dependence on fossil fuels, resulting in substantial savings on energy bills. These savings are influenced by factors such as the prevailing energy prices in the region, the efficiency of the renewable energy systems, and the amount of renewable energy integrated into the plant’s operations.

For example, regions with high fossil fuel prices will experience more significant savings than regions with relatively low energy costs.

Government Incentives and Subsidies

Governments worldwide are increasingly offering incentives and subsidies to encourage the adoption of renewable energy technologies. These incentives can take various forms, including tax credits, grants, and rebates for renewable energy installations. The availability and magnitude of these incentives vary greatly across different regions, influenced by national policies and priorities. Understanding the specific incentives available in a particular region is crucial for optimizing the economic benefits of renewable-powered auto plants.

Economic Viability in Different Regions

The economic viability of renewable-powered auto plants varies considerably across different regions. Factors such as energy prices, government policies, and the availability of renewable resources significantly impact the profitability of these ventures. For example, regions with abundant solar resources and supportive government policies may present more favorable economic conditions for renewable-powered auto plants. Regions with limited renewable resources or unfavorable regulatory environments may face higher initial investment costs and potentially lower long-term returns.

Comparison of Projected ROI

| Factor | Renewable-Powered Plant | Conventional Plant |

|---|---|---|

| Initial Investment | High | Moderate |

| Long-Term Energy Costs | Low | High |

| Government Incentives | Potentially High | Low |

| Return on Investment (ROI) | Estimated at 12-15% over 10 years | Estimated at 8-10% over 10 years |

The table above provides a general comparison. Actual ROI figures will vary based on specific project details and regional conditions.

Technological Advancements

The burgeoning renewable energy sector is experiencing rapid advancements, fostering innovative solutions for powering the automotive industry. This progress is crucial for achieving sustainability goals in vehicle manufacturing and operation. Key areas of development include improved renewable energy generation, enhanced energy storage, and advancements in electric vehicle (EV) battery technology.The transition to renewable energy sources requires robust infrastructure and advanced technologies.

This encompasses not only efficient solar and wind power generation but also innovative methods for storing the generated energy to ensure consistent power supply, particularly vital for 24/7 operations in automotive manufacturing plants. The integration of these technologies promises significant environmental benefits and contributes to a more sustainable automotive landscape.

Latest Advancements in Renewable Energy Technologies

Recent advancements in renewable energy technologies have led to greater efficiency and cost-effectiveness. Solar panel technology, for instance, has seen significant improvements in photovoltaic (PV) cell efficiency, enabling higher energy yields from smaller surface areas. Wind turbine designs have also evolved, incorporating larger rotor diameters and more sophisticated aerodynamic designs to capture stronger and more consistent wind energy.

Innovative Methods for Energy Storage

The intermittent nature of renewable energy sources necessitates effective energy storage solutions. Researchers are actively exploring various approaches, including advanced battery technologies, pumped hydro storage, and compressed air energy storage (CAES). These methods are crucial for maintaining consistent power output in the auto plants, ensuring uninterrupted operations and minimizing reliance on fossil fuels.

Progress in Battery Technology for Electric Vehicles

Battery technology is rapidly evolving, driving the adoption of electric vehicles. Improvements in battery chemistry, cell design, and manufacturing processes have resulted in higher energy densities, longer lifespans, and improved safety features. This translates to increased driving range, reduced charging times, and more reliable performance for EVs.

Comparison of Battery Types

Different battery types possess varying characteristics, influencing their suitability for renewable-powered auto plants. Lithium-ion batteries, currently the most prevalent type, offer high energy density and relatively long lifespans. However, factors like material sourcing and potential environmental impact need careful consideration. Solid-state batteries are emerging as a promising alternative, showcasing potential for higher safety, energy density, and faster charging rates.

The choice of battery type depends on the specific application and the desired balance between performance, cost, and sustainability.

| Battery Type | Energy Density | Charging Time | Safety | Sustainability |

|---|---|---|---|---|

| Lithium-ion | High | Moderate | Moderate | Concerns about material sourcing |

| Solid-state | High (potential) | Fast (potential) | High (potential) | Potentially better material sourcing |

Future of Sustainable Materials

The automotive industry is increasingly focused on sustainable materials for vehicle manufacturing. Recycled materials, such as aluminum and steel, are being incorporated into production processes, reducing the environmental footprint of vehicles. Bio-based plastics and composites are also gaining traction, offering alternative materials derived from renewable sources. The ongoing research and development in these areas promise to create more environmentally friendly vehicles while maintaining high performance standards.

Companies are actively exploring the use of recycled materials in manufacturing, a key aspect of sustainable practices.

Societal and Ethical Implications

Renewable-powered auto plants represent a significant shift in the automotive industry, demanding careful consideration of their societal and ethical impacts. These considerations extend beyond the environmental benefits, encompassing job creation, community development, ethical sourcing, and social equity. A thorough understanding of these aspects is crucial for ensuring a sustainable and equitable transition to a greener future.The implementation of renewable energy technologies in the automotive sector presents numerous opportunities for societal advancement, while also posing some challenges.

This section explores the potential positive and negative consequences of this transition, focusing on job creation, community impact, material sourcing, and social equity. Careful planning and implementation are crucial to maximize the benefits and mitigate any potential harm.

Job Creation Potential in the Renewable Energy Sector

The transition to renewable energy necessitates a substantial workforce. New jobs are created in manufacturing, installation, maintenance, and research & development related to solar panels, wind turbines, and battery technologies. This sector’s growth can significantly reduce unemployment and contribute to economic development in various regions. For example, the expansion of solar farms often leads to job creation in construction, installation, and maintenance, stimulating local economies.

Impact on Local Communities and Economies

The establishment of renewable-powered auto plants can have a substantial impact on local communities. These plants can stimulate economic growth through job creation, increased tax revenue, and investment in infrastructure. However, the relocation of existing industries or the impact on local businesses must be considered. Careful planning and community engagement are vital to ensure a positive and equitable outcome.

Examples include supporting local businesses through procurement and promoting skills training to prepare the workforce for new roles.

Ethical Considerations in Sourcing Raw Materials

The production of renewable energy components and electric vehicle batteries often involves sourcing raw materials from various countries. Ethical considerations include ensuring fair labor practices, environmental protection, and transparency in the supply chain. Companies must actively address potential issues such as conflict minerals, deforestation, and human rights abuses in their supply chains. This involves diligent due diligence and establishing strong partnerships with suppliers who adhere to ethical standards.

Potential for Social Equity and Inclusivity in These Plants

The transition to renewable energy can foster social equity and inclusivity if carefully planned. This includes providing training and education opportunities for underrepresented groups, ensuring fair wages and working conditions, and promoting diversity within the workforce. Community engagement and participation in the decision-making processes can also ensure the benefits are distributed equitably. This is crucial to avoid exacerbating existing inequalities and to ensure the transition benefits all members of society.

Summary of Societal Benefits of Renewable-Powered Auto Plants

| Societal Benefit | Description |

|---|---|

| Job Creation | The transition creates new jobs in manufacturing, installation, maintenance, and research. |

| Economic Growth | Increased tax revenue, investment in infrastructure, and local business support. |

| Community Development | Stimulating local economies, and addressing the potential impact on existing industries. |

| Ethical Sourcing | Ensuring fair labor practices, environmental protection, and supply chain transparency. |

| Social Equity | Providing training and education opportunities, fair wages, and promoting diversity. |

Operational Strategies

Optimizing energy production and consumption within a renewable-powered auto plant is crucial for its efficiency and sustainability. Proper integration of renewable energy sources, coupled with meticulous energy management, is paramount to maximizing output while minimizing environmental impact. Effective maintenance and safety protocols for renewable energy equipment are equally critical for long-term viability and worker safety.Integrating renewable energy sources into the plant’s operations necessitates a holistic approach, moving beyond mere installation to encompass operational optimization.

This involves strategic planning to ensure the plant’s energy needs are met reliably and cost-effectively. A well-defined energy management system is essential for monitoring and controlling energy usage across all plant processes.

Energy Production and Consumption Optimization

Strategies for optimizing energy production and consumption within the plant include maximizing the output of renewable energy sources, such as solar and wind farms, and minimizing energy losses throughout the manufacturing process. This entails utilizing advanced energy storage technologies to buffer fluctuations in renewable energy generation and implementing demand-side management techniques to adjust energy consumption in real-time. For example, variable-speed drives for motors can significantly reduce energy consumption compared to traditional fixed-speed drives.

Renewable Energy Source Integration

A phased approach to integrating renewable energy sources is vital. Initial steps might focus on grid-connected solar panels to supplement existing energy infrastructure, gradually transitioning to more complex systems like wind turbines and battery storage. Careful consideration must be given to the intermittency of renewable energy sources, and strategies for energy storage and grid stabilization need to be in place.

This could involve partnering with local utility companies to facilitate energy trading and grid management.

Energy Management Procedure

A comprehensive energy management system is essential for tracking and optimizing energy usage across all plant operations. A step-by-step procedure could involve:

- Data Collection: Monitoring energy consumption from various sources (solar, wind, grid) and production stages within the plant using real-time data collection systems.

- Analysis and Reporting: Analyzing collected data to identify patterns, inefficiencies, and areas for improvement in energy usage.

- Targeted Interventions: Implementing strategies to address identified inefficiencies, such as optimizing machine operation schedules, improving insulation in production areas, and implementing smart controls for lighting and HVAC systems.

- Continuous Improvement: Regularly reviewing energy performance data and adjusting strategies to maintain optimal energy efficiency.

Maintenance and Repair Strategies

A proactive maintenance schedule is critical for renewable energy equipment. Regular inspections, preventative maintenance, and timely repairs can significantly extend the lifespan of components, minimize downtime, and ensure optimal performance. A detailed maintenance schedule should be developed, taking into account the specific characteristics of each renewable energy system. This schedule should consider the expected lifespan of equipment and the frequency of routine checks.

Safety Protocols

Strict safety protocols are paramount for handling and storing renewable energy sources, especially considering the potential for hazardous materials in some energy storage systems. These protocols should address safe handling procedures for materials, equipment operation, and emergency response plans. For example, strict guidelines for the safe transportation, storage, and disposal of batteries used in energy storage systems are essential.

Case Studies of Existing Plants

Current efforts towards sustainable energy integration in the automotive sector are increasingly relying on case studies of successful renewable-powered auto plants. These examples provide valuable insights into the practical implementation of renewable energy technologies, showcasing the potential for large-scale adoption. Analyzing these case studies helps to understand the key success factors and challenges, enabling better planning for future projects.Analyzing existing renewable-powered auto plants offers a practical framework for understanding the intricacies of integrating sustainable energy sources.

These studies provide a nuanced perspective on the real-world implementation of renewable energy, revealing successes and challenges encountered in various contexts. This section will highlight specific examples, detailing their technological approaches, operational characteristics, and overall success factors.

Examples of Successful Renewable-Powered Auto Plants

Examining existing successful models of renewable-powered auto plants provides valuable lessons for future developments. These case studies illustrate the practical application of renewable energy sources in manufacturing, revealing the nuances of integration.

- Plant A: Location – Southern Europe: This plant utilizes a combination of solar photovoltaic (PV) panels and wind turbines to generate electricity. The plant incorporates energy storage systems, such as battery banks, to manage fluctuations in renewable energy supply. Key success factors include optimized energy management software and robust partnerships with local energy providers. The plant’s integration of a microgrid allows it to operate independently during grid outages, enhancing reliability.

- Plant B: Location – North America: This plant leverages primarily hydroelectric power from a nearby dam. The plant’s design emphasizes energy efficiency through optimized production processes and the use of high-efficiency motors. Their success hinges on a strong relationship with the local utility and a commitment to rigorous energy audits and continuous improvement.

- Plant C: Location – Asia: This plant is a pioneer in utilizing biogas generated from agricultural waste. The plant’s innovative approach integrates waste management and energy production. Key success factors include strong community engagement and local support for the plant’s environmental benefits. The plant’s innovative approach includes capturing and converting agricultural waste into a usable energy source, reducing reliance on fossil fuels and creating a closed-loop system.

Technological Approaches Employed

Understanding the specific technologies employed in these plants is crucial for understanding the feasibility and practicality of their approaches.

- Plant A utilizes a hybrid system of solar PV and wind turbines. This approach diversifies the renewable energy sources, mitigating the variability of each. The integration of energy storage allows for greater stability and reliability of power supply.

- Plant B leverages hydroelectric power, which offers a stable and predictable energy source. This plant focuses on energy efficiency through optimized production processes and equipment.

- Plant C‘s innovation lies in biogas production from agricultural waste. This approach addresses waste management while producing a clean energy source. The closed-loop system minimizes environmental impact and fosters sustainable practices.

Operational Details

Understanding the operational specifics provides context for evaluating the sustainability and scalability of these models.

| Plant | Location | Energy Source(s) | Capacity (MW) | Operating Hours |

|---|---|---|---|---|

| Plant A | Southern Europe | Solar PV, Wind | 10 | 24/7 |

| Plant B | North America | Hydroelectric | 15 | 24/7 |

| Plant C | Asia | Biogas | 5 | 24/7 |

Success Factors

Examining the factors contributing to the success of these plants highlights best practices for future implementations.

- Plant A‘s success stems from the integration of energy storage systems, which allow for efficient use of fluctuating renewable energy sources. Strong partnerships with local energy providers are also vital for long-term sustainability.

- Plant B‘s success is primarily attributed to the stable nature of hydroelectric power. Efficient production processes and energy audits are key components in maintaining operational excellence.

- Plant C‘s success hinges on strong community engagement and the innovative integration of waste management with energy production. This fosters support and minimizes environmental impact.

Future Trends

The future of renewable-powered auto plants hinges on the convergence of technological advancements, economic incentives, and societal demands. Projections indicate a significant shift towards sustainable manufacturing, with renewable energy sources becoming increasingly integral to the production process. This transition is not merely a trend, but a crucial step towards achieving a cleaner and more sustainable future for the automotive industry.

Integration of Smart Grids and Automation

The integration of smart grids with automated systems within renewable-powered auto plants promises significant efficiency gains. Real-time energy management, enabled by smart grids, allows for dynamic adjustments to energy consumption, optimizing production schedules and minimizing waste. Automated processes, such as robotic arms and automated material handling systems, further enhance efficiency and reduce operational costs. This synergy is crucial for achieving sustainable production targets and ensuring consistent energy supply.

Potential for Further Cost Reductions

Continued advancements in renewable energy technologies, coupled with economies of scale, are expected to drive down the costs associated with renewable-powered auto plants. The decreasing price of solar panels and wind turbines, along with improvements in energy storage technologies, are contributing factors. Furthermore, the adoption of automation and optimized production processes can lead to reduced labor costs and improved overall efficiency, thereby lowering the production cost per vehicle.

Examples of this include Tesla’s Gigafactories, which demonstrate the potential for large-scale, efficient production facilities.

Development of New Renewable Energy Sources

The exploration and development of new renewable energy sources, such as advanced solar technologies and geothermal energy, are crucial for a more diversified and resilient energy supply. These innovations can enhance the reliability of renewable energy sources, particularly in regions with limited access to traditional renewable energy options. For example, advancements in concentrated solar power (CSP) offer the potential for significant increases in power generation during peak demand periods.

Role of AI in Optimizing Renewable Energy Utilization

Artificial intelligence (AI) plays a pivotal role in optimizing renewable energy utilization within auto plants. AI-powered algorithms can analyze real-time data on energy production, consumption, and grid conditions. This allows for predictive maintenance, proactive adjustments to energy consumption patterns, and optimal allocation of renewable energy sources. The result is a more efficient and cost-effective operation, minimizing reliance on fossil fuels and maximizing the benefits of renewable energy.

Examples of AI applications include the use of machine learning to predict solar irradiance and optimize solar panel positioning.

Regulatory Frameworks and Policies

Establishing renewable-powered auto plants requires a robust regulatory framework to facilitate their development and ensure environmental sustainability. This framework needs to consider various aspects, from permitting processes to incentives and support for the industry. Clear guidelines are crucial to mitigate risks, encourage innovation, and foster a conducive environment for investment.

Key Regulations and Policies

Governments worldwide have enacted various regulations pertaining to renewable energy sources. These regulations often encompass standards for energy efficiency, emissions reduction, and the integration of renewable energy into the national grid. Compliance with these regulations is essential for the smooth operation and legitimacy of renewable-powered auto plants. Specific regulations may include mandates for renewable energy procurement, carbon emission limits, and standards for the sourcing of raw materials.

Incentives and Support

Governments often provide incentives and support to promote the development of renewable energy technologies. These incentives can take various forms, such as tax credits, subsidies, grants, and feed-in tariffs. These support mechanisms are designed to lower the financial burden on developers and attract investment in the sector. For example, tax credits for the use of renewable energy sources in manufacturing or investment in renewable energy infrastructure can substantially reduce the project costs and encourage private sector participation.

Permitting Processes

The permitting process for building renewable-powered auto plants varies significantly across regions. This process involves navigating local regulations, environmental impact assessments, and community engagement. Clear and transparent permitting procedures are vital for project efficiency and to avoid delays. Potential delays can be caused by inadequate or overly complex procedures. Streamlined procedures and clear timelines will encourage timely project completion.

Challenges and Opportunities for Implementing New Regulations

Implementing new regulations for renewable-powered auto plants presents both challenges and opportunities. One challenge is the need to balance environmental protection with economic competitiveness. Another challenge is the varying levels of awareness and expertise within local authorities and regulatory bodies. Opportunities arise from the potential for job creation, economic growth, and the development of a sustainable industry.

Innovative solutions and collaboration between government agencies and industry stakeholders are vital for addressing these challenges.

Regulatory Landscape for Renewable-Powered Auto Plants

| Region | Key Regulations | Incentives | Permitting Process |

|---|---|---|---|

| Europe | EU Renewable Energy Directive, national emission standards | Tax credits, grants, feed-in tariffs | Varying by country, typically involves environmental impact assessments and local consultations |

| United States | State and federal renewable energy standards, emission standards | Tax credits, grants, state-specific incentives | State-specific permitting processes, often with environmental impact review |

| China | National renewable energy targets, emission standards | Government subsidies, tax incentives | National and local permitting procedures, possibly with streamlined processes for strategic projects |

| India | National policies on renewable energy, emission standards | Government support schemes, fiscal incentives | State-specific procedures, likely to become more streamlined for renewable energy projects |

This table provides a general overview; specific regulations and processes can vary within each region.

Design and Implementation of a Renewable Energy System

A sustainable auto plant necessitates a robust renewable energy system. This system must be meticulously designed and implemented to ensure reliable power generation, minimizing reliance on traditional fossil fuel sources. Careful consideration of factors like energy storage, distribution, and building materials is paramount for maximizing efficiency and minimizing environmental impact.The design and implementation of a renewable energy system for an automotive plant involve a complex interplay of technological advancements and practical considerations.

Renewable-powered auto plants are a promising development, aiming for a cleaner automotive industry. Safety features like a proper seat belt cutter, essential for emergency situations, are crucial alongside these innovations. Seat belt cutter technology is critical for ensuring quick access in accidents. Ultimately, the goal remains sustainable, safe, and efficient renewable-powered auto plants.

The system must be scalable and adaptable to meet future demands while maintaining operational efficiency and cost-effectiveness.

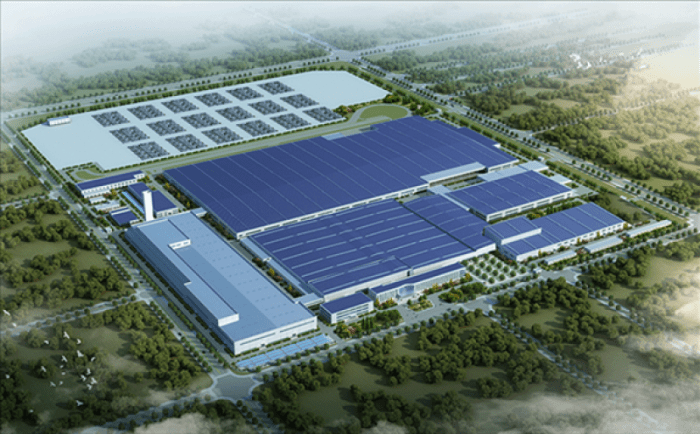

Conceptual Diagram of a Renewable-Powered Auto Plant

The conceptual diagram for a renewable-powered auto plant integrates various renewable energy sources. The core idea is to maximize energy capture and minimize reliance on the grid.  Description: A schematic diagram illustrating the layout of a renewable-powered auto plant. The diagram shows solar panels positioned on the roof of the plant, and wind turbines strategically placed near the plant.

Description: A schematic diagram illustrating the layout of a renewable-powered auto plant. The diagram shows solar panels positioned on the roof of the plant, and wind turbines strategically placed near the plant.

A large energy storage facility, likely a battery bank, is shown connected to the plant’s energy distribution network.

Placement and Integration of Renewable Energy Sources

A careful assessment of local weather patterns and available land is critical for optimal placement of renewable energy sources.

- Solar Panels: Solar panels are positioned on the rooftops of the plant buildings, maximizing sunlight exposure. This approach minimizes land use and integrates seamlessly with existing structures. Panels are angled for optimal sunlight capture throughout the year, and shading is accounted for.

- Wind Turbines: Wind turbines are strategically placed outside the plant perimeter in areas with consistent wind speeds, ensuring maximum energy generation. Environmental impact assessments are crucial to minimize noise pollution and visual impact. Proximity to the plant and wind patterns are key factors in placement.

- Other Sources: Geothermal energy, if available, can be integrated to provide a consistent energy source, especially in areas with geothermal activity. This can complement solar and wind, providing a reliable backup and baseload.

Energy Storage Methods

Effective energy storage is crucial for maintaining consistent power supply, particularly during periods of low solar or wind output.

- Battery Storage: Large-scale battery storage systems, likely lithium-ion batteries, are essential for storing excess energy generated during peak production. This enables the plant to function reliably even when renewable energy sources are unavailable.

- Pumped Hydro Storage: If feasible, pumped hydro storage can be used, providing a large-scale energy storage option, particularly if the geographical area allows for such implementation. This method involves using excess energy to pump water uphill, and retrieving it later to generate power.

Energy Distribution Network

The energy distribution network is crucial for efficient and reliable energy transfer within the plant.

- Smart Grid: A smart grid, utilizing advanced sensors and control systems, monitors and optimizes energy flow throughout the plant, dynamically adjusting to varying demands. This enhances efficiency and reduces energy waste.

- Microgrids: Microgrids can be used to isolate certain areas of the plant, allowing for localized energy management and potentially reducing dependence on the broader grid during outages.

Sustainable Building Materials

Sustainable building materials are integral to the environmentally conscious design of the auto plant.

- Recycled Materials: The use of recycled materials in construction significantly reduces the plant’s environmental footprint. This includes steel, concrete, and other construction components.

- Low-Carbon Concrete: Low-carbon concrete blends can be used to reduce the carbon footprint associated with concrete production. This is a key consideration in minimizing the plant’s overall environmental impact.

- Sustainable Wood: Sustainable forestry practices can be employed to procure wood for the construction of specific plant components. This includes timber from responsibly managed forests.

- Renewable Materials: Employing renewable building materials, like bamboo or hempcrete, further contributes to a sustainable design approach. This is an effective strategy to minimize the reliance on traditional construction materials.

Ultimate Conclusion

In conclusion, renewable-powered auto plants are not just a technological advancement; they represent a fundamental shift towards a more sustainable and responsible automotive industry. The economic, environmental, and societal benefits are substantial, paving the way for a cleaner and more resilient future. While challenges remain, the potential for widespread adoption of these plants is immense.

FAQ Overview

What are the most common types of renewable energy sources used in these plants?

Solar, wind, and hydro power are frequently employed, but geothermal and biomass can also play a role, depending on location and specific needs.

What are the potential government incentives for building these plants?

Many governments offer tax credits, grants, and subsidies to encourage investment in renewable energy projects. Specific incentives vary by region and may include tax deductions for capital expenditures.

How does waste reduction and recycling contribute to the environmental benefits?

Renewable-powered auto plants often incorporate innovative waste management systems. Recycling materials from the manufacturing process minimizes environmental impact and conserves resources.

What are some of the challenges in implementing these plants in developing countries?

Developing countries may face challenges related to infrastructure, financing, and skilled labor. However, these issues can often be mitigated with international partnerships and tailored support programs.