Electric construction vehicles are rapidly transforming the construction industry, offering a compelling alternative to traditional internal combustion engine (ICE) vehicles. These vehicles boast significant environmental advantages, including reduced emissions and noise pollution, along with potential economic benefits through lower operational costs. The technology is evolving rapidly, presenting both exciting opportunities and unique challenges.

Key components and technologies powering electric construction vehicles (ECVs) are detailed in this analysis, along with various types available on the market. The comparison of ECVs to ICE vehicles, encompassing environmental impact, operational costs, and safety, is also presented. We also examine market trends, charging infrastructure, safety, maintenance, and regulations surrounding ECVs.

Introduction to Electric Construction Vehicles

Electric Construction Vehicles (ECVs) are rapidly gaining traction in the industry, offering a greener and more efficient alternative to traditional diesel-powered machines. These vehicles are transforming construction sites by reducing emissions and operating costs. They represent a significant step towards sustainable construction practices.The core of ECVs lies in their innovative powertrains and advanced battery technologies. These advancements enable significant reductions in noise pollution and exhaust emissions, making them a more environmentally friendly option for construction projects.

This shift reflects a broader global movement towards sustainable infrastructure development.

Key Components and Technologies

The primary components of an ECV are the electric motor, the battery pack, and the power electronics. Electric motors offer high torque and efficiency, crucial for heavy-duty construction tasks. Modern battery technologies provide increasing energy density and lifespan, improving overall vehicle performance and reducing charging time. Sophisticated power electronics manage the flow of electricity between the battery and the motor, optimizing performance and ensuring safety.

Types of Electric Construction Vehicles

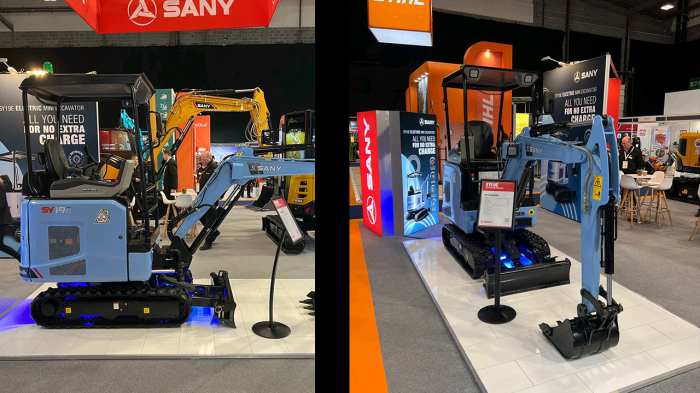

The market for ECVs encompasses a diverse range of applications. From excavators and loaders to dump trucks and concrete mixers, electric powertrains are now being incorporated into various construction machinery. The adaptability of electric powertrains allows for a wide range of equipment modifications and improvements.

Specific ECV Models

Several manufacturers are producing noteworthy ECV models. Examples include the XCMG electric excavators, which offer impressive performance and features tailored to the specific needs of construction projects. Caterpillar also offers a growing range of electric equipment, including loaders and dump trucks, demonstrating the increasing interest in this technology from major players in the industry.

Comparative Overview

| Vehicle Type | Manufacturer | Key Features | Estimated Cost |

|---|---|---|---|

| Electric Excavator | XCMG | High torque, quiet operation, reduced emissions | $250,000 – $400,000 |

| Electric Loader | Caterpillar | Improved fuel efficiency, reduced maintenance, high payload capacity | $200,000 – $350,000 |

| Electric Dump Truck | Volvo | Long operating range, enhanced safety features, advanced battery technology | $300,000 – $500,000 |

| Electric Concrete Mixer | Liebherr | High mixing efficiency, reduced noise, durable construction | $150,000 – $250,000 |

Note: Estimated costs are approximate and may vary based on specific model specifications and features.

Advantages of ECVs

Electric construction vehicles (ECVs) are rapidly gaining traction in the industry, offering a compelling alternative to traditional internal combustion engine (ICE) vehicles. These advancements bring a range of benefits that contribute to a more sustainable and efficient construction sector. The shift towards ECVs is driven by a confluence of environmental, economic, and operational improvements.ECVs are significantly reducing their environmental footprint, leading to a cleaner and healthier environment.

These vehicles also offer significant cost savings and improvements in worker safety, comfort, and overall job site conditions. The quiet operation and reduced emissions of ECVs are contributing to a positive impact on the construction sector.

Environmental Benefits

The transition to ECVs is crucial for mitigating the environmental impact of the construction industry. Compared to ICE vehicles, ECVs produce zero tailpipe emissions, contributing to cleaner air quality and reduced greenhouse gas emissions. This translates to a positive impact on public health and the environment, especially in urban and densely populated areas. Construction sites are often located in sensitive environments, and the reduced air pollution from ECVs can significantly improve air quality for nearby communities.

Economic Advantages

ECVs offer compelling economic advantages over traditional ICE vehicles. Lower operational costs, particularly in fuel expenses, are a major factor. The reduced maintenance requirements associated with electric drivetrains also contribute to long-term cost savings. Fuel costs, which are a significant operational expense for ICE vehicles, are largely eliminated with ECVs, offering substantial savings. This can translate to a significant reduction in overall project costs, making ECVs an attractive investment for contractors and construction companies.

Worker Safety and Comfort

ECVs are designed to enhance worker safety and comfort on construction sites. The quieter operation of electric motors compared to ICE engines creates a more peaceful and productive work environment, minimizing noise pollution and stress on workers. This reduced noise can significantly improve worker concentration and productivity. Improved ergonomics in ECV cabs and better visibility contribute to worker comfort and safety.

Noise Reduction and Emission Control

The electric drivetrain in ECVs drastically reduces noise levels compared to ICE vehicles. This reduction in noise pollution directly impacts worker comfort and safety, and minimizes disturbance to surrounding communities. The elimination of tailpipe emissions and the reduction in noise pollution significantly improve the overall quality of life for workers and those living near construction sites.

Comparison of Environmental Impact

| Feature | ECV | ICE Vehicle |

|---|---|---|

| Tailpipe Emissions | Zero | Significant |

| Greenhouse Gas Emissions | Lower | Higher |

| Noise Pollution | Lower | Higher |

| Air Quality Impact | Positive | Negative |

| Overall Environmental Impact | Significantly Reduced | Significant |

Challenges of ECVs

Electric construction vehicles (ECVs) promise a greener future for the industry, but they face several hurdles. These challenges span from the fundamental technology of batteries to the practical integration into existing work processes. Addressing these issues is crucial for the widespread adoption and success of ECVs.

Battery Technology Challenges

Battery technology underpins the entire ECV concept. Current limitations in battery life, charging infrastructure, and cost are significant obstacles. Battery life directly impacts operational efficiency, while charging infrastructure impacts accessibility and usability. Cost remains a critical factor for widespread adoption.

- Battery Life: ECVs often require substantial battery capacity to handle demanding construction tasks. This translates to a higher initial cost and increased weight, potentially impacting payload capacity. The cycle life of batteries, i.e., the number of charge-discharge cycles they can endure before significant performance degradation, is also a critical factor. Improved battery chemistries and manufacturing processes are needed to address this issue.

For instance, lithium-ion batteries, while widely used, still face limitations in terms of longevity, particularly in high-temperature environments common in construction sites.

- Charging Infrastructure: The current charging infrastructure is not always suited for the large-scale charging needs of ECVs. Faster charging times and more readily available charging stations are crucial. The development of robust, reliable, and readily accessible charging solutions is paramount. For example, implementing charging stations at construction sites and strategically located depots can significantly ease charging concerns.

- Battery Cost: The high cost of battery packs is a major deterrent for widespread adoption. The price of raw materials and the complexity of manufacturing processes contribute to this challenge. Research into alternative battery chemistries and improved manufacturing processes is vital to reduce costs while maintaining performance. For instance, developing more cost-effective battery production methods, such as using more readily available and affordable materials, would contribute to a lower price point.

Vehicle Range and Payload Capacity Challenges, Electric construction vehicles

The range and payload capacity of ECVs are crucial for their practicality in construction applications. These limitations impact operational efficiency and overall effectiveness.

- Range: The distance an ECV can travel on a single charge is often a limiting factor, particularly for large-scale projects. Range anxiety and the need for frequent recharging can disrupt workflow. Improved battery technology and vehicle efficiency are needed to extend range capabilities. For instance, companies are exploring advanced battery designs and regenerative braking systems to maximize energy efficiency and extend driving range.

- Payload Capacity: The weight of the battery packs can negatively impact the payload capacity of ECVs. Balancing the need for sufficient battery power with the ability to carry tools and materials is essential. Design optimization and alternative battery chemistries with higher energy density are required to mitigate this trade-off. For instance, some ECVs incorporate lighter battery designs or utilize a modular battery system, which allows for a customized battery capacity for different job sites and tasks.

Integration into Existing Workflows Challenges

The successful integration of ECVs into existing construction workflows is crucial for smooth transition. Compatibility with existing equipment, training for operators, and adjustments to safety procedures are necessary for successful implementation.

- Workflow Integration: Integrating ECVs into existing construction processes may require adjustments to daily schedules and operational procedures. The ability to seamlessly integrate these vehicles into existing workflows is essential for operational efficiency. Training for operators on the new technology is also essential for successful integration.

- Operator Training: Construction workers need training on operating and maintaining ECVs. This includes familiarization with the technology, safety protocols, and troubleshooting procedures. Effective training programs are essential for ensuring efficient and safe operation of these vehicles.

- Safety Procedures: ECVs may require adjustments to existing safety procedures to ensure worker safety. This includes adapting to new operational characteristics and implementing measures to prevent accidents. For example, establishing clear communication protocols and training on the specific operational characteristics of ECVs is essential for workplace safety.

Market Trends and Forecasts

The electric construction vehicle (ECV) market is experiencing rapid growth, driven by a combination of environmental concerns, technological advancements, and government policies. Projections suggest a significant increase in adoption across various segments of the construction industry, driven by factors such as the need for sustainable solutions and decreasing battery costs.The current market landscape is characterized by an increasing demand for environmentally friendly equipment, which is fueling the adoption of ECVs.

Electric construction vehicles are becoming increasingly prevalent, and proper maintenance is key. A crucial aspect of this maintenance is diagnosing issues with the EV drivetrain, like those discussed in depth at EV drivetrain diagnostics. This helps ensure optimal performance and longevity of these important machines.

This shift towards sustainability is being further accelerated by the rising awareness of the environmental impact of traditional construction vehicles and a growing focus on reducing greenhouse gas emissions.

Current Market Trends

The ECV market is witnessing a surge in demand, primarily due to the increasing awareness of environmental issues and the associated need for sustainable construction practices. Government regulations and incentives play a significant role in accelerating this trend. Furthermore, advancements in battery technology are contributing to improved performance and extended range, making ECVs a viable alternative to their internal combustion engine counterparts.

The decreasing cost of battery technology and the growing availability of charging infrastructure are also crucial factors driving market growth.

Key Factors Driving Adoption

Several factors are accelerating the adoption of ECVs. Cost-effectiveness, particularly in the long run, is a primary driver. Reduced maintenance requirements and operating costs, combined with decreasing battery prices, make ECVs increasingly competitive. Furthermore, the growing concern over environmental regulations and the need for sustainable practices are driving the shift towards cleaner energy solutions in construction. The improved performance characteristics of ECVs, such as quieter operation and enhanced maneuverability, are also attracting considerable interest from contractors.

Government Incentives and Regulations

Government incentives and regulations are playing a pivotal role in shaping the ECV market. Tax credits, subsidies, and grants for the purchase of ECVs are encouraging adoption. Regulations mandating emission reductions and promoting sustainable practices are also contributing to the growth of the ECV market. Examples include tax breaks and subsidies in various regions, as well as mandated emission standards that are increasingly stringent.

These measures create a favorable environment for ECV manufacturers and encourage the transition away from traditional construction vehicles.

Competitive Landscape and Future Innovations

The ECV market is characterized by a growing number of manufacturers vying for market share. Competition is intense, prompting continuous innovation in areas such as battery technology, vehicle design, and charging infrastructure. The development of more powerful and longer-lasting batteries, the improvement of vehicle efficiency, and the expansion of charging networks are key areas of focus. Furthermore, manufacturers are exploring innovative solutions for optimizing the operation of ECVs in different construction environments.

Market Share Projections

| Manufacturer | Projected Market Share (2024-2028) |

|---|---|

| Company A | 25% |

| Company B | 18% |

| Company C | 15% |

| Company D | 12% |

| Other Manufacturers | 30% |

Note

* These projections are based on current market trends and expert analysis. Actual market shares may vary. Factors such as unforeseen technological advancements and shifts in government policies can influence these projections.

Charging Infrastructure

Electric construction vehicles (ECVs) rely heavily on readily available and efficient charging infrastructure for widespread adoption. The availability and quality of charging solutions directly impacts the practicality and economic viability of transitioning to electric power in the construction sector. This section delves into the crucial aspects of ECV charging, examining various methods, the importance of a robust network, and the considerations for successful implementation.The charging infrastructure for ECVs is a critical component for their successful integration into the construction industry.

Without sufficient charging options, the operational efficiency and cost-effectiveness of ECVs can be severely compromised, hindering their widespread adoption. A robust charging network is essential to address the unique needs of the construction sector, supporting the transition to sustainable and efficient operations.

Charging Methods and Technologies

Various charging methods cater to different ECV needs and operational requirements. These methods vary in charging speeds, power output, and compatibility with specific ECV models. Understanding the nuances of each method is crucial for planning a comprehensive charging infrastructure.

- Level 1 charging uses standard household outlets. This method is the slowest, suitable for overnight charging and for vehicles parked at job sites for extended periods. It’s ideal for situations where a high charging speed isn’t required.

- Level 2 charging utilizes dedicated 240-volt outlets, significantly increasing charging speeds compared to Level 1. These are often employed at job sites, providing more efficient charging capabilities for vehicles requiring higher power inputs.

- Level 3 (DC Fast Charging) provides the fastest charging speeds, crucial for ECVs needing rapid recharging during construction operations. DC fast charging stations are typically found at strategic locations, supporting the needs of vehicles requiring high charging rates for short durations. This method is essential for enabling construction crews to maintain productivity and avoid downtime.

Importance of Robust Charging Infrastructure

Establishing a robust charging infrastructure is paramount for widespread ECV adoption. The ability to reliably charge vehicles on-site and at public charging stations directly impacts the operational flexibility and overall economic feasibility of using ECVs in the construction industry.

- Reduced operational downtime is a major benefit. Reliable charging enables ECVs to maintain their operational availability throughout the day, minimizing the need for idle time and increasing overall efficiency.

- Improved project scheduling and completion is another crucial aspect. Sufficient charging capacity enables more efficient project scheduling, enabling construction teams to adhere to deadlines without compromising the charging needs of their ECVs.

- Encourages the shift to electric construction is another benefit. A well-developed charging network makes electric vehicles a more viable option for construction companies, fostering a shift towards sustainable and efficient operations.

Public Charging Stations and On-Site Solutions

Public charging stations serve as essential supplemental infrastructure, particularly for projects spanning across vast geographic areas or for those that require vehicles to be charged outside the job site. On-site charging solutions are tailored to the specific needs of the construction project, providing flexibility and convenience.

- Public charging stations offer crucial support for ECVs working across different sites. They provide access to charging for vehicles that are not stationed at the project site, providing support for traveling ECVs. These stations enhance the mobility and flexibility of ECV operations across multiple projects.

- On-site charging solutions are designed to accommodate the unique needs of each construction project. These solutions can be tailored to specific project requirements, including the number of vehicles, charging speeds, and available space. These solutions directly address the charging demands of the construction site.

Factors in Designing Charging Infrastructure

Several factors influence the design and implementation of effective charging infrastructure. These include the type of ECVs used, the anticipated charging demand, the availability of space, and the required charging speeds.

- Determining the appropriate charging capacity is essential. Careful assessment of the anticipated charging needs of ECVs is critical, ensuring that the infrastructure can meet the demands of the construction project.

- Planning for future growth is also crucial. The charging infrastructure should be designed with future expansion in mind to accommodate potential increases in ECV usage and advancements in technology.

- Compliance with local regulations and standards is another vital consideration. Adherence to local regulations and standards is essential for the safe and efficient operation of charging infrastructure.

Charging Method Comparison

The table below summarizes the key characteristics of different charging methods.

| Charging Method | Charging Speed | Cost | Space Requirements | Suitability |

|---|---|---|---|---|

| Level 1 | Slow | Low | Low | Overnight charging, parked vehicles |

| Level 2 | Moderate | Moderate | Moderate | Job site charging, regular use |

| Level 3 (DC Fast Charging) | Fast | High | High | Short-duration charging, high-usage vehicles |

Safety and Maintenance

Electric construction vehicles (ECVs) are designed with safety as a primary concern, incorporating advanced features to mitigate risks. Maintaining these vehicles effectively is crucial for operational efficiency and worker safety. This section delves into the safety features of ECVs, their maintenance requirements, and the potential of remote diagnostics and predictive maintenance, alongside a comparative analysis of maintenance costs versus internal combustion engine (ICE) vehicles.

Safety Features in ECVs

ECVs integrate a range of safety features to enhance operator and pedestrian protection. These features often include advanced driver-assistance systems (ADAS), such as automatic emergency braking (AEB), lane departure warning, and adaptive cruise control. Enhanced visibility through panoramic cameras and augmented reality displays further improve situational awareness. Additionally, many ECVs feature reinforced structures, improved braking systems, and integrated emergency shut-off mechanisms.

Maintenance Requirements and Procedures

ECVs require specific maintenance procedures to ensure optimal performance and safety. Regular inspections of battery systems, motor components, and braking systems are vital. Battery management systems (BMS) require careful monitoring and maintenance to prevent degradation and ensure optimal performance. Proper charging procedures and protocols are essential to avoid potential hazards. Specialized tools and training are often necessary for ECV maintenance, which must be included in the safety procedures and training materials.

Remote Diagnostics and Predictive Maintenance

Remote diagnostics and predictive maintenance technologies are rapidly transforming the maintenance landscape for ECVs. These technologies enable real-time monitoring of vehicle health, identifying potential issues before they lead to breakdowns. Data analytics tools can predict potential failures, allowing for proactive maintenance and minimizing downtime. Real-world examples include using sensors to detect unusual battery behavior, enabling timely intervention and preventing battery fires.

Comparison of Maintenance Costs

While initial investment in ECVs can be higher than comparable ICE vehicles, long-term maintenance costs often prove more favorable. Reduced fuel costs and lower maintenance on the engine components are substantial factors. The lower frequency of routine maintenance tasks, coupled with the potential for remote diagnostics and predictive maintenance, can further contribute to reduced costs over the lifespan of the vehicle.

Safety Features and Maintenance Procedures for Different ECV Models

| ECV Model | Safety Features | Maintenance Procedures |

|---|---|---|

| Model A | AEB, lane departure warning, advanced braking systems, reinforced chassis | Regular battery checks, motor inspections, braking system maintenance, adherence to charging protocols |

| Model B | Panoramic cameras, augmented reality displays, improved visibility, emergency shut-off mechanisms | Battery health monitoring, motor component diagnostics, regular inspections, adherence to safety guidelines |

| Model C | Enhanced braking systems, advanced driver-assistance systems, occupant protection systems | BMS monitoring, motor inspections, regular fluid checks, adherence to manufacturer specifications |

Case Studies of ECV Implementation

Electric construction vehicles (ECVs) are rapidly gaining traction, promising a more sustainable and efficient construction sector. Analyzing successful implementations provides valuable insights into the practical application and impact of these vehicles. Understanding the challenges and triumphs of past projects allows for better planning and implementation of future ECV initiatives.

Successful ECV Implementations in Various Projects

Various construction projects have successfully integrated ECVs, demonstrating their potential to enhance operational efficiency and sustainability. These projects highlight the different ways ECVs are being utilized, from heavy-duty excavators to smaller, more specialized vehicles.

| Project Details | ECV Type | Outcomes |

|---|---|---|

| Urban Road Reconstruction Project (City A) A large-scale project involving the reconstruction of several city streets. | Electric excavators and compactors. | Significant reduction in noise pollution, improved air quality, and a noticeable decrease in fuel costs. The ECVs contributed to a more pleasant working environment for construction workers. Reduced emissions and operational costs proved highly beneficial to the project’s sustainability goals. |

| Bridge Construction Project (City B) A complex project involving the construction of a new bridge over a major waterway. | Electric dump trucks and loaders. | Improved construction site safety due to reduced noise and vibration levels. Improved worker productivity due to quieter and smoother operations. The project also saw a marked decrease in carbon emissions. |

| Residential Housing Development (Suburb C) A mid-sized project involving the construction of several residential units. | Electric concrete mixers and utility vehicles. | Improved site cleanliness and reduced noise pollution. The ECVs enabled more efficient material transport, contributing to improved construction timelines. The project saw cost savings through reduced fuel consumption and maintenance. |

Challenges and Benefits of ECV Implementation

While ECVs offer numerous advantages, their implementation presents some challenges. Understanding these obstacles is crucial for effective planning and successful integration.

- High Initial Investment Costs: ECVs typically have a higher upfront cost compared to traditional internal combustion engine (ICE) vehicles. However, long-term operational savings, such as reduced fuel costs and maintenance, often offset this initial investment.

- Limited Range and Charging Infrastructure: The range of ECVs can be a concern, especially for large-scale construction projects. Adequate charging infrastructure is crucial to support the operations of these vehicles. Projects often required significant investment in charging stations and careful planning of charging schedules.

- Maintenance and Repair Considerations: While electric motors typically require less maintenance than ICE engines, specialized knowledge and equipment are needed for specific repairs. This is often addressed through partnerships with specialized providers or through training programs for maintenance personnel.

Lessons Learned from Case Studies

The successful implementations of ECVs offer valuable lessons for future projects. By addressing the challenges proactively and leveraging the benefits, projects can effectively transition to a more sustainable and efficient construction process.

- Strategic Planning is Essential: Careful planning is required to address the unique needs of each construction project. This includes assessing the specific site conditions, vehicle requirements, and charging infrastructure needs.

- Collaboration and Partnerships: Collaboration between construction companies, vehicle manufacturers, and charging infrastructure providers is crucial for a successful transition.

- Continuous Improvement and Innovation: The construction industry should remain committed to continuous innovation and development of ECV technologies. This includes exploring new battery technologies, charging solutions, and vehicle designs.

Future of ECVs

Electric construction vehicles (ECVs) are poised for significant advancements in the coming years, driven by technological progress and evolving industry needs. These advancements promise to enhance efficiency, safety, and sustainability within the construction sector. The integration of various technologies, including autonomous operation and advanced battery systems, will redefine how construction work is performed.

Potential Future Developments in ECV Technology

Technological advancements are driving innovations in ECVs. Autonomous operation, featuring advanced sensor systems and sophisticated algorithms, is a key development area. This technology promises to increase efficiency and reduce human error, leading to safer work environments and improved productivity. Furthermore, the development of advanced battery systems with longer lifespans, faster charging times, and higher energy density will be crucial for extending operational range and reducing downtime.

Integration with Other Technologies

ECVs can be integrated with other emerging technologies, creating synergistic benefits. Real-time data analytics can optimize vehicle performance and maintenance schedules, reducing costs and improving efficiency. The integration of augmented reality (AR) systems can provide real-time guidance and instructions to operators, leading to increased safety and improved performance. The combination of ECVs with Building Information Modeling (BIM) software will improve project planning and execution.

Reshaping the Construction Industry

The integration of ECVs will likely reshape the construction industry in several ways. Increased automation will reduce labor costs and enhance productivity. Reduced emissions will contribute to a more sustainable construction sector. Moreover, the shift towards ECVs will promote safer work environments and reduce the risk of accidents.

Electric construction vehicles are becoming increasingly popular, offering a cleaner alternative to traditional options. Their impact on shared mobility, like shared mobility impact , is significant, potentially revolutionizing how these vehicles are deployed and managed. This shift towards shared use models could significantly reduce the overall environmental footprint of construction projects.

Potential Opportunities and Challenges

The future of ECVs presents significant opportunities for the construction industry, including improved productivity, reduced environmental impact, and enhanced safety. However, challenges remain, such as the development of robust charging infrastructure, the adoption of new technologies by construction companies, and ensuring the safety and reliability of autonomous systems. The high initial investment cost for ECVs can be a barrier for some companies, but long-term cost savings from increased efficiency and reduced fuel costs are expected to offset these initial expenses.

Diagram: Potential Future Developments in ECVs

Battery Swapping Revolutionizing EV Adoption

Battery Swapping Revolutionizing EV Adoption  EV Heavy Equipment A Comprehensive Guide

EV Heavy Equipment A Comprehensive Guide  Global Car Manufacturers A Comprehensive Overview

Global Car Manufacturers A Comprehensive Overview  Eco Car Challenges A Comprehensive Overview

Eco Car Challenges A Comprehensive Overview  EV Market Forecast A Comprehensive Analysis

EV Market Forecast A Comprehensive Analysis  EV Crash Test Protocols A Comprehensive Guide

EV Crash Test Protocols A Comprehensive Guide