Dual clutch transmission offers a unique blend of performance and efficiency. This technology, designed to seamlessly transition between gears, provides a dynamic driving experience. It combines the responsiveness of a manual transmission with the convenience of an automatic. Understanding its intricacies, advantages, and potential drawbacks is key to appreciating this sophisticated system.

This in-depth exploration of dual clutch transmissions delves into the mechanics, performance benefits, and practical considerations, making it a valuable resource for anyone interested in automotive engineering and driving dynamics.

Introduction to Dual Clutch Transmission (DCT)

A dual-clutch transmission (DCT) is an advanced automatic transmission design that offers a blend of smooth shifting and improved fuel efficiency compared to conventional automatic transmissions. It accomplishes this by employing two clutches, allowing for rapid gear changes without the interruption experienced in traditional automatics. This efficiency and speed make DCTs a popular choice in many modern vehicles, especially those focused on performance and fuel economy.

Fundamental Working Principles of a DCT

The core principle behind a DCT lies in its ability to pre-select the next gear while the vehicle is in the current gear. This pre-selection minimizes the time it takes to transition between gears, resulting in smoother and quicker shifts. The system uses two clutches, one for each gear set. When shifting, one clutch disengages while the other engages, allowing for a seamless transition.

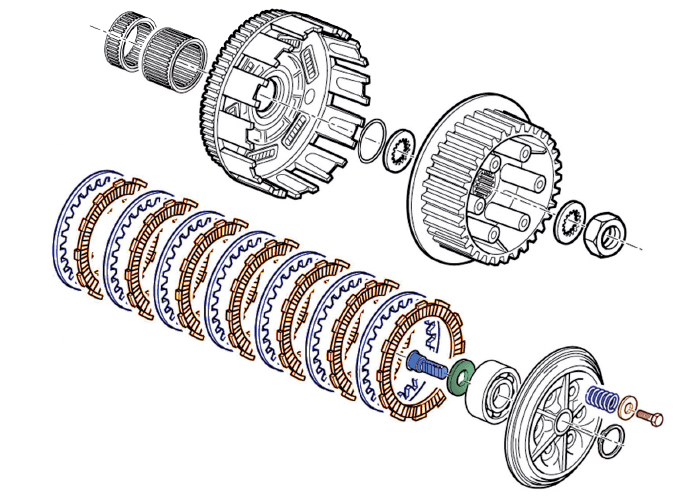

Key Components of a DCT System

The DCT system consists of several interconnected components, each playing a crucial role in its operation.

- Two clutches: These are the heart of the DCT system. Each clutch is responsible for engaging a specific gear set. The synchronized engagement and disengagement of these clutches are essential for smooth gear changes.

- Two sets of gears: A DCT typically has two sets of gears, each corresponding to an even and odd gear set. This allows the transmission to pre-select the next gear set while the vehicle is in the current gear.

- Control unit: A sophisticated control unit manages the complex interactions between the clutches and the gear sets. It receives signals from the vehicle’s sensors and adjusts the clutch engagement and disengagement timing for optimal performance and fuel efficiency. This unit is critical in coordinating the rapid and precise shifts that DCTs are known for.

- Hydraulic system: A hydraulic system often supports the operation of the clutches. It provides the necessary force for engaging and disengaging the clutches, ensuring smooth and reliable operation.

Diagram of DCT Components

The following diagram illustrates the interaction between the key components of a DCT.

| Component | Description |

|---|---|

| Clutch 1 | Engages the gear set for odd-numbered gears. |

| Clutch 2 | Engages the gear set for even-numbered gears. |

| Gear Set 1 | Contains gears for odd-numbered gear ratios. |

| Gear Set 2 | Contains gears for even-numbered gear ratios. |

| Control Unit | Coordinates the engagement and disengagement of clutches and the shifting of gears. |

Note: This is a simplified diagram. In reality, DCTs can have additional components and intricate mechanisms for even greater precision and performance.

Advantages of DCT

Dual-clutch transmissions (DCTs) offer a compelling blend of performance, efficiency, and responsiveness, making them a popular choice for many modern vehicles. They stand apart from traditional automatic transmissions by leveraging the benefits of a manual transmission’s quick shifting capabilities within an automatic transmission’s convenience. This unique approach translates into a more engaging driving experience and improved fuel economy.

Performance Benefits

DCTs excel in performance due to their ability to shift gears significantly faster than traditional automatic transmissions. This rapid shifting allows for quicker acceleration and improved responsiveness. By pre-selecting the next gear, the DCT can smoothly transition between gears without the interruptions associated with traditional automatic transmissions. This seamless gear shifting contributes to a more spirited driving experience.

Drivers experience reduced lag and a more immediate response to the accelerator input.

Fuel Efficiency Advantages

DCTs often demonstrate superior fuel efficiency compared to traditional automatic transmissions. The ability to quickly select the most appropriate gear for the current driving conditions allows the engine to operate at its most efficient RPM range. This optimized performance reduces energy loss associated with inefficient gear changes and allows for more consistent power delivery. In certain situations, DCTs can even match or exceed the fuel efficiency of manual transmissions.

This advantage is particularly pronounced in highway driving, where the DCT can maintain higher gear ratios.

Improved Drivability and Responsiveness

The responsiveness of DCTs is a significant advantage. The precise and quick gear changes provide a more dynamic driving experience, allowing for quicker acceleration and smoother transitions. This translates to a more engaging driving experience, making the vehicle feel more responsive to driver input. The seamless transitions between gears contribute to a quieter and more refined driving experience.

Furthermore, DCTs provide a more direct connection to the engine compared to some traditional automatic transmissions.

Comparison Table

| Transmission Type | Acceleration | Fuel Efficiency | Drivability | Cost |

|---|---|---|---|---|

| Manual | Excellent, but requires driver input | Generally high | Direct and engaging | Generally low |

| Traditional Automatic | Good, but often slower than DCT | Moderate | Comfortable and convenient | Moderate |

| DCT | Excellent, matching or exceeding manual transmissions | High, often comparable to manual | Engaging and responsive, with smoother shifting | Moderate to high |

The table above provides a comparative overview of key performance metrics across different transmission types. It highlights the strengths of DCTs in terms of acceleration, fuel economy, and drivability, while also acknowledging the trade-offs in cost. These metrics are influenced by factors like vehicle design, engine specifications, and driving conditions. It’s essential to remember that real-world results can vary based on the specific vehicle and driving habits.

Disadvantages of DCT

Dual-clutch transmissions, while offering many advantages, are not without their drawbacks. Understanding these limitations is crucial for making informed decisions about vehicle purchase and maintenance. These disadvantages often manifest in higher costs, potential reliability issues, and specific operational challenges.

Cost Considerations

DCTs typically involve more complex mechanical components compared to conventional automatic transmissions. This complexity translates to higher manufacturing costs. As a result, vehicles equipped with DCTs often command a premium price tag. The increased manufacturing cost is reflected in the final retail price, making DCT-equipped vehicles more expensive than their equivalent counterparts with traditional transmissions.

Reliability and Maintenance Concerns

DCTs, despite their sophistication, can experience reliability issues. The intricate clutch and gear shifting mechanisms are more susceptible to wear and tear than simpler automatic transmissions. Problems such as clutch slippage, premature clutch wear, and gear-shifting problems can lead to costly repairs. The more intricate nature of DCTs demands more specialized maintenance, requiring specialized tools and skilled technicians, which can increase the cost of repair and maintenance over time.

The high cost of parts and labour for repair further exacerbates the issue.

Harsh Shifts and Engagement Issues

Some DCT models have been criticized for harsh or unpredictable shifts. The rapid engagement and disengagement of clutches can sometimes result in jarring sensations, impacting the driving experience. This is particularly noticeable during acceleration and deceleration. This can lead to a less refined driving experience and reduced driver comfort, especially in comparison to smoother shifts of other transmission types.

Harsh engagement can also potentially lead to a higher frequency of repairs if the issues are severe enough.

Dual clutch transmissions are known for their smooth gear changes, but ultimately, the cost of the car, including factors like financing options and monthly car payments , plays a significant role in the overall expense. These transmissions, while offering a quicker shift response, don’t necessarily translate to lower overall ownership costs, so consider the full picture when making your purchase decision.

Premature Wear and Tear on Specific Components

The rapid cycling of clutches in DCTs can lead to premature wear and tear on clutch packs and related components. The constant engagement and disengagement of the clutches can put significant stress on these components, potentially reducing their lifespan. This can lead to increased maintenance costs and potentially more frequent replacement cycles for these parts compared to traditional transmissions.

Examples of this can be seen in instances where vehicles with DCTs require clutch replacements or repairs significantly earlier than predicted, thus increasing the cost of ownership.

Applications of DCT

Dual-clutch transmissions (DCTs) have become increasingly prevalent in various vehicle types due to their ability to provide smooth gear changes and enhanced fuel efficiency. Their adaptability and performance advantages have led to their adoption across a wide range of applications.DCTs offer a unique blend of performance and efficiency, which makes them a compelling choice for a diverse range of vehicles.

This adaptability, combined with their performance characteristics, has contributed to their widespread use in different vehicle segments.

Examples of Vehicles Utilizing DCT Technology

DCTs are prevalent in numerous vehicle types, extending beyond high-performance models. Their advantages make them suitable for a variety of applications. Common examples include:* Many sporty compact cars and mid-size sedans benefit from DCT’s quick shifting.

- Numerous luxury vehicles also incorporate DCTs for enhanced driving experience.

- Performance-oriented SUVs and crossovers often feature DCTs for improved acceleration and responsiveness.

Industries Where DCTs are Commonly Employed

DCT technology is not confined to a single industry. Their versatility allows for widespread use across various sectors.* The automotive industry is a primary adopter of DCTs due to their positive impact on fuel efficiency and performance.

- The need for smooth and rapid shifting in high-performance vehicles has driven DCT adoption in the sports car market.

- DCTs have shown to improve the performance and efficiency of various commercial vehicles like trucks and vans.

Specific Applications of DCTs in Different Vehicle Types

DCTs are well-suited for diverse vehicle types. Their smooth shifting and quick response time make them ideal for a variety of driving situations.* In high-performance vehicles, DCTs provide quick and precise gear changes, contributing to exceptional acceleration and responsiveness.

- For everyday passenger cars, DCTs offer a comfortable driving experience, providing smooth transitions between gears and enhancing fuel efficiency.

- Commercial vehicles, including trucks and vans, often benefit from the enhanced durability and reliability of DCTs, which are vital for heavy-duty applications.

DCT Applications Categorized by Vehicle Type and Use Case

The following table summarizes the diverse applications of DCT technology, categorized by vehicle type and the specific use case.

| Vehicle Type | Use Case |

|---|---|

| Sporty Compact Cars | Enhanced acceleration and responsiveness, quick gear changes |

| Luxury Sedans | Smooth and refined driving experience, superior fuel efficiency |

| Performance SUVs/Crossovers | Combining high performance with fuel efficiency |

| Commercial Vehicles (Trucks/Vans) | High-torque applications, durability, and reliability |

DCT Design Considerations

Dual-clutch transmissions (DCTs) present a complex interplay of design choices, each impacting performance, efficiency, and cost. Understanding these considerations is crucial for optimizing the design and functionality of DCT systems. From clutch design to shift strategies, numerous factors need careful attention to ensure a seamless and responsive driving experience.Careful design choices in DCTs are vital to achieving the desired performance characteristics, including smooth shifting, quick acceleration, and fuel efficiency.

Trade-offs between these aspects frequently arise, requiring a balanced approach to design.

Dual clutch transmissions are known for their smooth gear changes and quick acceleration. This efficiency could play a crucial role in future vehicle applications, like vehicle to grid systems, where vehicles can act as power sources. The advanced shifting capabilities of a dual clutch transmission make it ideally suited for the demands of these dynamic energy management systems.

Clutch Synchronization

Accurate synchronization of the clutches is fundamental to the smooth operation of a DCT. Precise timing in engagement and disengagement of the clutches ensures minimal impact and jerking during gear changes. This synchronization is achieved through sophisticated control systems that monitor various parameters, such as engine speed, vehicle speed, and load conditions. The control unit precisely manages the engagement and disengagement of the clutches, ensuring a seamless transition between gears.

Shifting Strategies

Optimizing the shifting strategy is critical for achieving rapid and smooth gear changes. DCTs typically employ sophisticated algorithms to predict the optimal shift points, taking into account various driving conditions. The strategy aims to minimize the time spent in the transition phase, which is the period between the disengagement of one clutch and the engagement of the next.

Factors like engine speed, vehicle speed, and load are considered in determining the optimal shift point.

Clutch Design

The design of the clutches in a DCT directly impacts the overall performance of the transmission. Factors like friction material, clutch plate geometry, and spring characteristics all influence the engagement force, wear resistance, and durability. The selection of materials and the design of the clutch assembly are crucial in balancing the conflicting requirements of high engagement force, smooth operation, and durability.

This balance is achieved through careful analysis of the various parameters involved.

Control System Design

The control system of a DCT plays a vital role in coordinating the operation of the clutches and the selection of gears. Advanced control strategies are employed to ensure optimal performance, which involves monitoring various vehicle parameters, such as engine speed, vehicle speed, and load. This information is then used to make real-time adjustments to the shifting strategy, ensuring a smooth and efficient driving experience.

The complexity of the control system reflects the sophisticated nature of DCT operation.

Materials Selection

The selection of materials for various components in a DCT is crucial for achieving optimal performance and durability. The materials need to withstand the high stresses and temperatures encountered during operation. Factors such as friction coefficients, wear resistance, and temperature stability are key considerations in the material selection process. The selection of the most suitable materials is critical for minimizing wear and tear, extending the lifespan of the transmission, and ensuring the required performance.

DCT Maintenance and Repair: Dual Clutch Transmission

Dual-clutch transmissions (DCTs) require specific maintenance procedures to ensure optimal performance and longevity. Proper maintenance significantly reduces the likelihood of costly repairs and extends the transmission’s lifespan. Ignoring routine checks and services can lead to premature wear and tear, potentially causing significant problems.A well-maintained DCT will provide smooth gear changes, enhanced fuel efficiency, and a more enjoyable driving experience.

Regular inspection and maintenance are crucial for preventing potential issues and maximizing the return on investment for vehicles equipped with this advanced transmission technology.

Typical Maintenance Procedures

Routine maintenance is vital for DCTs, mirroring the importance of servicing other transmissions. These procedures are designed to prevent small problems from escalating into major failures. Regular inspections and servicing, like those for conventional transmissions, are essential for maintaining optimal performance.

- Fluid changes are critical. DCTs use specialized fluids designed for their specific operating conditions. Improper fluid type or inadequate fluid levels can lead to premature wear and friction. Fluid changes should be performed according to the manufacturer’s recommendations to ensure the transmission operates within its designed parameters.

- Regular filter replacements are essential. The transmission filter removes contaminants and debris from the fluid. Clogged filters can restrict fluid flow and cause overheating or damage to internal components. Regular filter replacements help maintain clean fluid and optimal performance.

- Thorough inspections for wear and tear are important. Visual inspections, including checking for leaks, unusual noises, and component damage, are crucial. Identifying potential problems early can prevent them from escalating.

- Component lubrication and adjustments are necessary. DCT components need lubrication to reduce friction and wear. Regular lubrication ensures smooth operation and extends component lifespan. Adjustments may be needed for optimal performance, ensuring smooth gear changes and avoiding excessive wear.

Common Problems and Repair Strategies

Several issues can affect DCTs. Addressing these problems promptly can prevent further damage. Diagnostics and repairs should be performed by qualified technicians experienced with DCT technology.

- Clutch slippage is a common issue. Slippage occurs when the clutch doesn’t engage properly, leading to rough gear changes and potential damage. Diagnosing the cause of slippage (e.g., worn clutch packs, faulty hydraulics) and performing the appropriate repair (e.g., clutch replacement, hydraulic component repair) is critical for resolving the issue.

- Gear shifting problems are another common issue. These problems manifest as rough or delayed shifts. Diagnosing the root cause, whether it’s a faulty control module, worn synchronizers, or incorrect fluid levels, is key to resolving the shifting issue.

- Overheating is a significant concern. Overheating can lead to irreversible damage to internal components. Identifying the cause of overheating (e.g., insufficient cooling, blocked radiator) and implementing appropriate repairs (e.g., radiator cleaning, fan repair) is critical to prevent further damage.

- Electrical problems can affect DCT operation. Malfunctions in the control system or sensors can disrupt proper operation. Diagnosing and repairing these electrical problems is crucial for restoring proper functionality.

Significance of Regular Maintenance, Dual clutch transmission

Regular maintenance procedures are crucial for extending the life of a DCT. Preventing problems from escalating to major failures is a key benefit. Regular maintenance can significantly reduce repair costs and downtime.

- Regular maintenance helps prevent premature wear. Proactive maintenance can prevent minor issues from becoming major repairs, reducing downtime and maintenance costs.

- Preventive maintenance reduces repair costs. Catching problems early avoids expensive repairs and replacements.

- Regular maintenance helps maintain optimal performance. A well-maintained DCT ensures smooth and reliable operation.

Step-by-Step Guide for Diagnosing DCT Issues

A systematic approach to diagnosing DCT issues is essential. This involves a series of steps to isolate the problem and facilitate efficient repairs. Detailed records of the vehicle’s history are important for proper diagnostics.

- Gather vehicle history and documentation, including previous maintenance records and repair history.

- Inspect for any visible signs of damage, leaks, or unusual noises.

- Conduct a thorough visual inspection of the transmission components.

- Assess the transmission fluid levels and condition. Check for discoloration, unusual smells, and contamination.

- Use diagnostic tools to identify any fault codes or error messages. Consult the vehicle’s technical documentation for specific diagnostic procedures.

- Run the transmission through its operating range and note any unusual behavior.

- Consult with a qualified technician to confirm the diagnosis and recommend the appropriate repair.

DCT Evolution and Future Trends

The dual-clutch transmission (DCT) has undergone significant evolution since its inception, transforming from a niche technology to a widely adopted solution in various automotive applications. This evolution is driven by continuous advancements in design, materials, and control systems, aiming to enhance performance, efficiency, and durability. This section details the historical development of DCT technology, highlighting key advancements, and explores potential future innovations.

Historical Development of DCT Technology

Early DCT designs were primarily focused on achieving smooth gear shifts and reduced transmission drag. The initial implementations faced challenges in achieving a seamless transition between clutches, leading to some performance compromises. However, continuous research and development led to significant improvements in clutch engagement, control algorithms, and overall transmission architecture.

- The initial iterations of DCTs emerged in the late 1990s and early 2000s. These early systems were primarily used in high-performance applications and were limited by the complexity of their design and the need for sophisticated control systems.

- Subsequent developments focused on improving efficiency, reducing friction losses, and enhancing durability. This led to the incorporation of advanced materials and manufacturing techniques.

- The availability of more powerful and efficient engines and electronic control units (ECUs) contributed to the refinement and wide adoption of DCTs in passenger vehicles.

Advancements and Improvements in DCT Design

Several advancements have propelled DCT technology forward. These advancements encompass various aspects of the transmission design, aiming to enhance the driving experience and reduce operational costs.

- Improvements in clutch technology, such as the development of friction materials with enhanced wear resistance and reduced friction, have significantly contributed to the overall performance and longevity of DCTs.

- Advanced control systems, utilizing sophisticated algorithms and sensors, provide precise and responsive clutch engagement, optimizing the shift quality and fuel efficiency.

- The integration of advanced materials, such as high-strength alloys and composites, has led to lighter and more robust transmission components, reducing overall vehicle weight.

This has a direct impact on fuel efficiency and performance.

Future Directions and Potential Innovations

The future of DCT technology hinges on several potential innovations. The ongoing trend is to improve efficiency, enhance performance, and address the challenges related to durability.

- One promising direction involves the exploration of hybrid DCT designs. This approach combines the benefits of DCTs with hybrid powertrain components, potentially leading to enhanced fuel efficiency and reduced emissions. Examples include electric DCTs, which leverage electric motors to assist in gear shifting.

- Research into novel clutch materials and designs is ongoing. This includes the exploration of materials with enhanced friction characteristics and reduced wear, as well as the development of more compact and efficient clutch mechanisms.

For instance, advanced materials like carbon fiber composites might be used in the future.

- The integration of advanced driver-assistance systems (ADAS) and autonomous driving features will likely influence DCT control systems. This integration might result in automated gear shifting and adaptive strategies for various driving conditions. Examples include automatic adjustments to shift patterns based on road conditions and driver preferences.

Timeline of Key Milestones in DCT Development

| Year | Milestone |

|---|---|

| Early 1990s | Initial research and development of DCT concepts. |

| Late 1990s | First commercial DCT applications in high-performance vehicles. |

| Early 2000s | Improvements in clutch technology and control systems. |

| Mid 2000s | Increased adoption of DCTs in passenger vehicles. |

| Present | Continued advancements in efficiency, performance, and durability, alongside exploration of hybrid designs. |

DCT vs. Other Transmission Types

Dual-clutch transmissions (DCTs) represent a significant advancement in automotive technology, offering a blend of performance and efficiency. Understanding their strengths and weaknesses, and comparing them to other transmission types, provides crucial insight into their suitability for various applications. This section delves into the contrasts between DCTs, manual transmissions, and traditional automatic transmissions.

DCT vs. Manual Transmissions

Manual transmissions offer a direct connection between the engine and the wheels, resulting in a strong sense of driving engagement. However, they require driver intervention for gear shifting, which can be demanding in certain driving conditions. DCTs, in contrast, automate this process, providing the same level of engagement but with a more convenient shifting experience. Drivers gain smoother transitions between gears, and this is particularly useful in city driving or situations requiring quick and precise gear changes.

The reduced driver workload leads to potentially improved fuel efficiency.

DCT vs. Traditional Automatic Transmissions

Traditional automatic transmissions, while providing driver convenience, often sacrifice some level of performance and fuel efficiency compared to DCTs. DCTs, with their dual clutches, offer faster and smoother gear changes than automatics, leading to quicker acceleration and potentially improved fuel economy. Automatic transmissions typically employ a torque converter, which can introduce slippage and reduce responsiveness. DCTs, by contrast, use a direct connection, resulting in a more direct power transfer to the wheels.

Strengths and Weaknesses of Each Transmission Type

- Manual Transmissions: Strengths include a direct power transfer, potentially higher fuel efficiency in skilled drivers, and a strong sense of connection with the vehicle. Weaknesses include driver fatigue during extended driving, the need for precise and timely shifting, and a lack of driver convenience. Manual transmissions remain popular in high-performance vehicles due to their ability to maximize engine power.

- DCTs: Strengths include smooth and fast gear changes, a balance between performance and fuel economy, and a reduced driver workload. Weaknesses include higher initial cost compared to some automatic transmissions, and potential issues with durability if not maintained properly. DCTs are suitable for vehicles requiring quick responsiveness and fuel efficiency.

- Traditional Automatic Transmissions: Strengths include driver convenience and ease of use, particularly in difficult driving conditions. Weaknesses include reduced fuel efficiency compared to DCTs, potentially slower acceleration, and a lack of driver control over gear selection. Traditional automatics remain popular in applications prioritizing comfort and ease of operation.

Comparative Table

| Criterion | Manual Transmission | DCT | Traditional Automatic |

|---|---|---|---|

| Driver Control | High | Medium | Low |

| Shifting Speed | Variable (dependent on driver skill) | Fast and Smooth | Moderate |

| Fuel Efficiency | Potentially high (with skilled driver) | High | Moderate |

| Cost | Low | Medium | Low |

| Maintenance | Relatively simple | Potentially more complex | Relatively simple |

| Acceleration | High (with skilled driver) | High | Moderate |

| Comfort | Low | Medium | High |

DCT in Different Driving Conditions

Dual-clutch transmissions (DCTs) are designed for a broad range of driving scenarios, adapting their performance to various conditions and driving styles. Their quick shifts and efficient power delivery contribute to a dynamic driving experience, although their suitability varies based on the specific application. This section examines DCT performance in diverse driving conditions, highlighting the factors that influence their operation.DCTs exhibit distinct characteristics in different driving environments, adapting to the demands of each situation.

Their sophisticated control algorithms and mechanical design contribute to a smooth and responsive driving experience, although the specific advantages and disadvantages vary with the type of driving.

City Driving Performance

DCTs excel in urban environments due to their ability to maintain smooth and quick gear changes. The rapid shifts reduce the perceived lag often associated with traditional automatic transmissions, enhancing the overall driving experience. However, frequent stop-and-go conditions can lead to increased wear and tear on the clutches, as the transmission cycles through gears more frequently. This is because the frequent shifting demands a greater number of clutch engagements.

Highway Driving Performance

Highway driving often benefits from the DCT’s ability to maintain a consistent gear ratio for optimal fuel efficiency. The seamless gear changes, especially at higher speeds, contribute to a more refined driving experience. Long stretches of constant speed provide optimal conditions for the DCT to operate efficiently.

Off-Road Driving Performance

DCTs are not typically designed for off-road conditions. Their primary focus is on efficiency and responsiveness on paved surfaces. The complexities of off-road driving, with varying terrain and load conditions, often exceed the capabilities of DCTs. The transmission’s sophisticated design might not handle the significant torque demands and uneven load distributions characteristic of off-road situations. This could potentially cause damage to the components.

Adaptation to Different Driving Styles

DCTs are generally responsive to various driving styles, although individual experiences may vary. Aggressive drivers may find the rapid gear changes enhance the driving experience, while more conservative drivers appreciate the smoothness and efficiency. The responsiveness to throttle input is a significant factor, allowing for a tailored driving experience.

Factors Affecting DCT Performance

Several factors influence DCT performance across different driving conditions:

- Driving Style: Aggressive driving styles, with frequent acceleration and deceleration, place higher demands on the transmission, potentially leading to faster wear and tear on the clutches. Conversely, a calm driving style results in a more prolonged lifespan for the components.

- Road Conditions: Uneven or rough surfaces can introduce additional stress on the transmission system, potentially impacting performance and lifespan.

- Load Conditions: Heavier loads require more torque, and the DCT’s ability to handle this torque directly affects its performance and durability. This is especially critical for towing heavy loads.

- Temperature: Extreme temperatures can affect the lubricants and components within the transmission, impacting its overall performance and lifespan. High temperatures can degrade the lubricants, and low temperatures can make the system less responsive.

DCT Pros and Cons in Different Driving Conditions

DCTs offer a superior driving experience in most conditions, but they have limitations in specific scenarios.

| Driving Condition | Pros | Cons |

|---|---|---|

| City Driving | Smooth gear changes, responsive acceleration, quick shifts | Increased wear on clutches due to frequent shifting |

| Highway Driving | Efficient fuel consumption, smooth and precise shifts at high speeds | Limited off-road capability |

| Off-Road Driving | Not suitable for rough terrain due to design limitations | Not suitable for situations with high torque demands and inconsistent load conditions |

Wrap-Up

In conclusion, dual clutch transmissions represent a significant advancement in automotive technology, offering a compelling alternative to traditional transmissions. While they present some challenges regarding cost and maintenance, their performance and fuel efficiency advantages are substantial. This overview highlights the complexities and potential of this innovative technology.

Key Questions Answered

What are the common maintenance procedures for DCTs?

Regular fluid changes, filter replacements, and inspection of clutch components are crucial. Following the manufacturer’s recommended maintenance schedule is essential for longevity.

How does DCT fuel efficiency compare to other transmissions?

DCTs often exhibit better fuel economy than traditional automatic transmissions, particularly in consistent driving conditions, thanks to their optimized gear shifting.

What are the potential reliability issues with DCTs?

DCTs can be prone to clutch slippage or harsh shifting if not maintained properly. Early wear and tear on components can occur if not properly cared for.

What are the key components of a DCT system?

Key components include two clutches, a sophisticated control system, and a multi-speed gearbox. These components work in tandem to provide smooth gear changes.