CVT transmission, a continuously variable transmission, is revolutionizing automotive technology. This innovative system offers a unique approach to power delivery, significantly altering how vehicles accelerate, respond to driver input, and manage fuel efficiency. Its design, advantages, and disadvantages, along with maintenance considerations, are explored in detail below.

From its fundamental principles to emerging trends, this guide provides a thorough overview of CVT transmission technology, examining its various applications and the factors influencing its performance. We delve into the design considerations, performance metrics, and the environmental impact of this remarkable transmission system.

Introduction to CVT Transmission

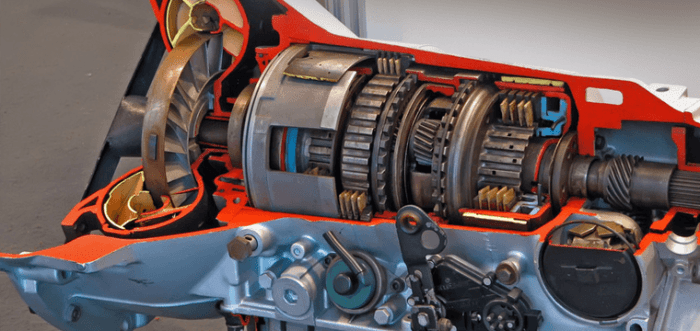

Continuously Variable Transmission (CVT) technology represents a significant advancement in automatic transmission design, offering a unique approach to power delivery. Unlike traditional automatic transmissions with a fixed number of gears, a CVT smoothly adjusts the ratio between engine output and wheel speed, leading to enhanced fuel efficiency and a generally smoother driving experience. This technology is increasingly popular in various vehicles, especially those emphasizing fuel economy and performance.The fundamental principle behind CVT operation is the use of two variable-diameter pulleys, typically made of durable materials like steel or composite materials, linked by a belt.

These pulleys are connected and their diameters are altered to provide a continuous range of gear ratios. The varying pulley diameters allow for a continuous power transmission ratio, unlike the discrete steps in traditional transmissions. This continuous variation enables the transmission to optimize engine speed for any given road condition, improving fuel efficiency and responsiveness.

CVT Design Types

Different CVT designs utilize various pulley configurations and belt materials to achieve optimal performance and durability. The most common types include:

- Variable-Diameter Pulleys with Belt Drive: This design is the most prevalent and features two pulleys of adjustable diameters. The belt connects these pulleys, transferring power continuously. This configuration provides smooth and efficient power transmission. Variations in this design include the use of different belt materials (e.g., steel belts or composite materials) and pulley configurations to adapt to different vehicle types and power requirements.

- Hydrostatic CVT: In this design, hydraulic pumps and motors are used to regulate the fluid pressure between two hydraulic pistons. This type of transmission has a continuous variation of speed ratio and is suitable for high-torque applications. While efficient, it is typically more complex and expensive compared to the belt-driven CVT.

Comparison with Traditional Automatic Transmissions

CVTs offer several advantages over traditional automatic transmissions. These include a wider range of operating speeds, leading to better fuel economy and a smoother driving experience. However, traditional automatic transmissions, with their discrete gear ratios, provide more predictable performance in certain driving conditions.

| Feature | CVT | Traditional Automatic Transmission |

|---|---|---|

| Gear Ratios | Continuous | Discrete |

| Fuel Economy | Generally higher | Variable, but often lower in modern CVTs |

| Driving Experience | Smoother | May have more noticeable shifts |

| Cost | Can be comparable or slightly higher | Typically lower |

| Maintenance | Potentially higher maintenance costs for certain CVT systems | Typically lower maintenance costs |

Key Components of a CVT System

A CVT system comprises several key components working together to achieve smooth and efficient power transmission.

- Variable-Diameter Pulleys: These pulleys are the core of the CVT system, adjusting their diameters to alter the gear ratio. High-quality materials are essential for durability and performance.

- Belt: The belt transmits power between the variable-diameter pulleys. The material and design of the belt must accommodate the power transmission and prevent slippage.

- Control System: The control system manages the diameter adjustments of the pulleys to match the vehicle’s needs. Sophisticated control systems optimize fuel efficiency and performance.

- Hydraulic System (in some CVT types): This system is present in some hydrostatic CVT designs and is crucial for the continuous power transmission mechanism.

Advantages and Disadvantages of CVT

Continuously Variable Transmissions (CVTs) have gained traction in the automotive industry due to their potential for enhanced fuel efficiency and smooth power delivery. However, they also present certain limitations compared to traditional automatic transmissions. This section delves into the strengths and weaknesses of CVT technology.

Benefits of CVT Transmissions

CVTs offer a continuous range of gear ratios, unlike traditional transmissions with discrete gear steps. This continuous variation allows for optimal engine speed matching at all operating conditions. This inherent characteristic leads to enhanced fuel efficiency.

- Enhanced Fuel Efficiency: The ability of a CVT to maintain optimal engine speed for a given vehicle speed results in reduced fuel consumption. Modern CVTs often utilize sophisticated control algorithms to optimize fuel efficiency, and studies have consistently shown improved fuel economy compared to traditional automatic transmissions in specific driving scenarios. For example, highway driving often benefits from the consistent optimal engine speed maintained by a CVT.

- Smooth Power Delivery: The continuous gear ratio variation in a CVT translates to a seamless power delivery experience. This smooth acceleration is a major appeal to drivers, offering a noticeably different driving experience compared to traditional automatic transmissions with their characteristic gear changes.

- Compact Design: The absence of discrete gear components in a CVT leads to a more compact transmission design. This characteristic is particularly valuable in applications where space is limited, such as in smaller vehicles or hybrids. Compactness can translate into weight savings in the vehicle, contributing to improved fuel efficiency.

Drawbacks and Limitations of CVT Transmissions

Despite the benefits, CVT transmissions have inherent limitations that affect their performance. One notable issue is the characteristic “whipping” or “noise” during acceleration, which can be undesirable for some drivers.

- Noise and Vibration: The lack of a traditional gear mechanism in a CVT can result in a noticeable “whipping” or “noise” sound during acceleration, particularly at low speeds. This characteristic can be jarring to some drivers and can affect the overall driving experience. This is often mitigated by advanced design and engineering efforts to reduce these issues.

- Potential for Inefficiency at Low Speeds: At low speeds, the CVT may exhibit less efficiency compared to other transmission types. This characteristic arises from the particular ratio changes employed at low speeds to match the engine and vehicle requirements. This issue is becoming less prevalent as technology evolves.

- Limited Torque Capacity: Some CVT designs may not handle high torque demands as effectively as other automatic transmissions. This can impact acceleration and performance in vehicles requiring significant torque output, such as heavy-duty vehicles or those towing heavy loads. This limitation is less significant in many passenger car applications.

Performance Comparison with Other Transmissions

Comparing CVT performance with other transmission types involves considering various factors. The fuel efficiency, responsiveness, and overall driving experience can differ depending on the specific vehicle and transmission design.

| Transmission Type | Fuel Efficiency | Responsiveness | Cost |

|---|---|---|---|

| CVT | Generally high, depending on design and driving conditions | Smooth, continuous acceleration | Typically competitive |

| Automatic | Moderate to high, varying by design | Step-wise acceleration, can feel less immediate | Typically competitive |

| Manual | Lower than CVT or automatic in most scenarios | Precise control over acceleration | Typically the lowest cost |

Impact on Fuel Efficiency

The inherent design of a CVT enables it to maintain optimal engine speed for a given vehicle speed. This optimization directly impacts fuel efficiency.

“Studies consistently show that CVTs can provide substantial fuel savings compared to other automatic transmissions, particularly in highway driving.”

Impact on Vehicle Acceleration and Responsiveness

The continuous variation of gear ratios in a CVT leads to smooth and continuous acceleration. This seamless power delivery translates into a generally responsive driving experience.

Applications of CVT Transmission

Continuously variable transmissions (CVTs) offer a unique approach to power delivery, allowing for a smooth and seamless range of speeds. This adaptability makes them suitable for a variety of vehicle types and applications, each benefiting from the transmission’s distinctive characteristics.CVTs excel in situations requiring a wide range of torque and speed ratios. Their inherent flexibility in adjusting gear ratios allows them to optimize fuel efficiency and performance across different driving conditions, from city commuting to highway cruising.

Examples of Vehicles Using CVT Technology

CVTs are increasingly prevalent in various vehicle segments. From compact cars to larger SUVs and even light trucks, the technology is finding its place in the automotive market. Notable examples include models from manufacturers like Honda, Toyota, Nissan, and Subaru. These examples showcase the adaptability of the CVT transmission.

Specific Applications Where CVT Transmissions Excel

CVTs thrive in applications requiring a wide torque range and a smooth power delivery. Fuel efficiency is a key benefit in many CVT applications. Their ability to maintain a close match between engine speed and wheel speed optimizes fuel economy. In stop-and-go city driving, CVTs can provide an advantage in terms of efficiency. Furthermore, the continuous variation of gear ratios allows for more seamless acceleration and deceleration, resulting in a refined driving experience.

This characteristic is particularly useful in urban environments.

Suitability of CVT for Different Types of Vehicles

The versatility of CVTs makes them suitable for a broad range of vehicles. Compact cars benefit from the fuel efficiency and smooth operation provided by CVTs. Larger SUVs and trucks can also utilize CVTs, though the specific design may differ to accommodate the increased torque demands. The choice of a CVT depends on the vehicle’s intended use and performance requirements.

Industries or Sectors Where CVT is Commonly Used

CVTs are gaining popularity in various sectors beyond personal transportation. Their use in agricultural machinery, for example, offers advantages in terms of power and efficiency. Industrial applications, where variable speed is crucial, also find benefits in CVT technology. The range of applications extends beyond personal vehicles, making them a valuable component in various industries.

Comparison of CVT Application in Different Vehicle Categories

| Vehicle Category | Advantages of CVT Application | Potential Limitations |

|---|---|---|

| Cars (Compact/Subcompact) | Excellent fuel economy, smooth operation, and responsiveness in city driving. | Potential for a less engaging driving experience compared to traditional transmissions in some situations. |

| SUVs | Smooth power delivery and efficiency, particularly in highway driving and towing light loads. | Might not provide the same towing capacity as other transmission types in heavier-duty situations. |

| Trucks (Light-Duty) | Efficient power delivery in a wide range of driving conditions, particularly in stop-and-go traffic. | May not provide the same level of torque as traditional transmissions in certain applications. |

CVT Maintenance and Repair

Maintaining a Continuously Variable Transmission (CVT) requires specific attention due to its unique design. Proper maintenance can significantly extend the life of the transmission and prevent costly repairs. This section details typical maintenance procedures, common problems, troubleshooting steps, and signs of malfunction.

Typical Maintenance Procedures

Routine maintenance is crucial for optimal CVT performance. Regular inspection and lubrication of critical components, like the belt and pulleys, are vital. This often involves checking for wear and tear, ensuring proper tension, and replacing components as needed. Consistent monitoring of fluid levels and quality is equally important.

Common Problems Associated with CVT Systems

CVT systems, while efficient, are susceptible to certain issues. Common problems include belt slippage, pulley damage, and fluid leaks. Belt slippage often results from improper tension or wear, while pulley damage can stem from impacts or prolonged use. Fluid leaks can be caused by worn seals or damaged hoses, leading to reduced lubrication and potential component failure.

Troubleshooting Steps for Various CVT Issues

Troubleshooting CVT issues requires a systematic approach. First, identify the specific symptoms. Then, assess the fluid level and condition. If the belt shows signs of slippage or damage, it should be replaced. Damaged pulleys need to be replaced as well.

If fluid leaks are present, repair or replace the affected seals or hoses.

Signs of CVT Malfunction

Various signs can indicate CVT malfunction. These include unusual noises, such as grinding or whining sounds, while operating the vehicle. Performance issues, such as hesitation or loss of power, may also signal problems. Vibration, slipping, or harsh shifting can also indicate a malfunction. Finally, unusual fluid levels or discoloration may signal potential issues with the CVT system.

CVT Fluid Changes, CVT transmission

Regular CVT fluid changes are essential for optimal transmission performance. A step-by-step guide for CVT fluid changes follows:

- Gather necessary materials: Ensure you have the correct CVT fluid specified by the vehicle manufacturer, a clean work area, drain pan, new drain plug washer, and appropriate tools for fluid removal and replacement.

- Warm up the engine: Allow the engine to warm up to operating temperature to ensure the fluid is more easily drained.

- Locate the drain plug: Consult your vehicle’s service manual for the exact location of the drain plug.

- Position the drain pan: Place the drain pan underneath the drain plug to catch the old fluid.

- Remove the drain plug: Carefully remove the drain plug and allow the old fluid to drain completely. Ensure no foreign materials are in the fluid drain.

- Replace the drain plug washer: Install a new drain plug washer before replacing the drain plug.

- Check the fill plug: Locate the fill plug and ensure it is free of debris or blockage.

- Add new fluid: Slowly add the recommended amount of new CVT fluid through the fill plug, checking the fluid level regularly.

- Check the level: Once the fluid is added, check the fluid level using the dipstick and adjust as needed.

- Verify the system: Operate the vehicle to test the transmission operation and ensure proper fluid circulation.

CVT Transmission Design Considerations

CVT transmissions, known for their smooth and efficient power delivery, demand meticulous design considerations to optimize performance, reliability, and longevity. Factors ranging from material selection to manufacturing processes play a critical role in achieving these goals. Understanding these considerations is key to developing innovative and robust CVT designs.Careful design is essential for achieving the desired performance characteristics of a CVT.

This involves optimizing the transmission’s ability to seamlessly adjust the gear ratio to match engine power output with the vehicle’s speed and load. This smooth transition is crucial for fuel efficiency and driver comfort.

Design Factors Influencing CVT Performance

Several factors directly influence the performance of a CVT. These factors include the geometry of the pulley system, the material properties of the components, and the manufacturing tolerances. Precise control over these parameters is vital for achieving the intended characteristics.

CVT transmissions are known for their smooth power delivery, but they can sometimes be underpowered, especially in high-performance applications. A hood scoop, like the ones found on many performance cars, Hood scoop , is often employed to improve airflow to the engine, potentially boosting performance. However, the impact on a CVT transmission’s performance is typically less significant compared to other transmission types.

The relationship between these two elements is quite interesting, and it’s often a trade-off for the driver.

- Pulley Geometry: The shape and dimensions of the pulleys significantly impact the transmission’s efficiency and responsiveness. Optimal pulley designs minimize slippage and maximize power transfer. For example, carefully crafted pulley profiles can reduce friction and improve energy conversion, resulting in improved fuel efficiency.

- Belt Material and Properties: The belt material and its characteristics play a crucial role in the CVT’s performance. The belt’s material properties, including tensile strength, wear resistance, and flexibility, directly affect the CVT’s durability and ability to transmit power smoothly over a wide range of speeds.

- Bearing Design and Lubrication: Proper bearing design and lubrication are essential for smooth operation and extended lifespan. Bearings experience significant stress during operation. High-quality bearings and suitable lubricants reduce friction and wear, ensuring reliable performance.

Materials Used in CVT Components

The selection of materials is critical for the durability and performance of CVT components. Materials must possess specific properties to withstand the stresses and wear associated with continuous operation.

- Belt Materials: High-performance polymers, reinforced composites, and even metal belts are used, each with specific advantages. The choice depends on the required strength, flexibility, and wear resistance.

- Pulley Materials: Materials like high-strength alloys, polymers reinforced with carbon fiber, or even lightweight metals like aluminum alloys are chosen for their strength, stiffness, and wear resistance.

- Bearing Materials: Bearings often use materials with excellent load-carrying capacity and low friction, such as precision-engineered steel alloys.

Manufacturing Processes

Precise manufacturing processes are critical to ensuring the accuracy and consistency of CVT components.

- Pulley Manufacturing: CNC machining, precision casting, or other advanced manufacturing techniques are often used to create the complex pulley profiles necessary for smooth operation.

- Belt Manufacturing: Specialized processes are needed to create belts with the required tensile strength, flexibility, and dimensional stability.

- Assembly: The precise assembly of the pulleys, belt, and other components is crucial for achieving the intended transmission characteristics. This includes meticulous alignment of parts and careful consideration of assembly tolerances.

Challenges and Innovations in CVT Design

Several challenges remain in CVT design. These include achieving wider operating ranges, improving efficiency, and reducing manufacturing costs. Significant research and development efforts continue to address these issues.

- Enhanced Efficiency: Research focuses on minimizing friction and maximizing energy transfer within the CVT system.

- Wider Operating Range: Designers strive to expand the speed and load ranges that the CVT can effectively manage.

- Reduced Manufacturing Costs: Efforts are ongoing to develop more cost-effective manufacturing techniques for CVT components.

Key Design Parameters for a Robust and Reliable CVT

Design parameters play a vital role in ensuring a robust and reliable CVT. These parameters need to be meticulously controlled to guarantee the transmission’s long-term performance.

- Material Selection: Choosing the appropriate material for each component based on its specific function, load, and operating conditions is essential.

- Dimensional Accuracy: Precise manufacturing and assembly tolerances are critical for the CVT’s performance and longevity.

- Manufacturing Consistency: Standardized manufacturing processes are vital for ensuring the consistent quality of CVT components across different production runs.

CVT Performance Metrics

CVT transmissions, known for their smooth and efficient power delivery, are evaluated based on a range of performance metrics. These metrics provide insights into the transmission’s overall efficiency, power delivery characteristics, and adaptability to varying driving conditions. Understanding these metrics is crucial for optimizing CVT design and selecting the appropriate transmission for specific applications.

Efficiency Metrics

Evaluating CVT efficiency involves examining several key parameters. Fuel economy is a critical indicator, directly reflecting the transmission’s ability to minimize energy loss during power transfer. The power loss due to friction and internal components within the CVT mechanism is also assessed. A lower power loss translates to improved overall efficiency. Other factors, such as torque converter efficiency (if applicable), also contribute to the overall fuel economy.

Performance Parameters

CVT performance encompasses various parameters that describe its responsiveness and adaptability to different driving conditions. Acceleration and deceleration rates are important factors, measuring how quickly the CVT can respond to driver input. Load-carrying capacity reflects the CVT’s ability to manage varying loads. This parameter is crucial for vehicles that operate under fluctuating loads, like towing or carrying heavy cargo.

The transmission’s response to extreme conditions, such as high or low temperatures, is also assessed to ensure reliable operation across a wide range of operating conditions.

Comparison with Other Transmissions

Comparing CVT performance metrics to those of other transmissions, such as automatic transmissions with fixed gear ratios, reveals distinct advantages and disadvantages. CVTs offer superior fuel economy in many cases, particularly at steady speeds, due to their ability to continuously adjust the gear ratio. However, their performance under high torque demands can be less impressive than automatic transmissions.

The acceleration characteristics can vary depending on the specific CVT design and the driving conditions.

CVT Performance Graphs

Graphs showcasing CVT performance metrics provide a visual representation of the transmission’s characteristics. A typical graph might plot fuel economy against speed, illustrating how fuel efficiency varies with different driving speeds. Another graph could depict acceleration time against load, showing how the CVT’s acceleration capability changes under different load conditions. Such graphs are essential tools for comparing different CVT designs and understanding their strengths and weaknesses.

For instance, a graph demonstrating the efficiency of a CVT under varying torque conditions could highlight its superior fuel economy at steady speeds compared to a traditional automatic transmission.

CVT Performance Variation with Driving Conditions

CVT performance varies significantly with different driving conditions. At steady speeds, the CVT’s continuous variable ratio allows for optimized fuel efficiency. During acceleration, the transmission adjusts quickly to maintain optimal power delivery, but this responsiveness may be less pronounced under extreme acceleration demands compared to transmissions with fixed gear ratios. Furthermore, the CVT’s performance in hilly terrain can vary based on the incline angle and the vehicle’s load.

For instance, a CVT might exhibit a slight decrease in fuel economy on steep inclines, though the overall fuel economy advantage over fixed-gear transmissions is maintained in most cases.

CVT Future Trends

Continual advancements in automotive technology are driving the evolution of continuously variable transmissions (CVTs). The focus on efficiency, performance, and integration with other vehicle systems is reshaping the future of CVTs. This section explores emerging trends, potential innovations, and the pivotal role of CVTs in the evolving landscape of automotive engineering.The ongoing push for enhanced fuel efficiency and reduced emissions continues to be a significant driver for CVT innovation.

This is particularly relevant in the context of electric vehicles, where optimizing energy management and transmission efficiency is crucial. Furthermore, the integration of CVTs with other vehicle systems, such as advanced driver-assistance systems (ADAS), is anticipated to redefine their capabilities.

Emerging Trends in CVT Technology

Several trends are shaping the future of CVT technology. These trends reflect the evolving needs of the automotive industry, including the shift towards electric vehicles and the integration of sophisticated control systems. These advancements aim to improve efficiency, performance, and durability.

- Enhanced Efficiency: CVTs are being designed with a greater emphasis on minimizing energy loss during operation. This involves improvements in component materials, lubrication systems, and control algorithms. For example, optimized gear ratios and friction reduction techniques are critical in achieving better fuel economy, particularly in hybrid and electric vehicles.

- Improved Durability: Future CVT designs will focus on enhancing the durability and reliability of the transmission components. Advanced materials, robust manufacturing processes, and improved testing protocols will contribute to a longer lifespan for CVTs, minimizing maintenance requirements.

- Integration with Electric Vehicle Systems: The increasing adoption of electric vehicles necessitates the optimization of CVTs for electric powertrain architectures. This involves developing strategies for managing energy flow and integrating the CVT’s control algorithms with the vehicle’s overall power management system.

- Advanced Control Systems: The use of advanced control systems is expected to optimize the CVT’s performance across various driving conditions. Sophisticated algorithms and sensor technologies will enable the transmission to dynamically adjust its characteristics based on real-time information, leading to improved responsiveness and efficiency.

Potential Innovations for Future CVTs

The potential for innovation in CVT design is substantial. New materials, innovative control strategies, and advancements in manufacturing techniques are expected to lead to improved performance and efficiency. Examples of these potential innovations include:

- New Materials: The use of advanced materials, such as composites and high-strength alloys, will contribute to reducing weight and increasing durability. This could result in more compact and efficient CVTs.

- Advanced Control Algorithms: The development of more sophisticated control algorithms will allow the CVT to adapt to varying driving conditions more effectively. This will enhance the transmission’s responsiveness and fuel efficiency.

- Compact Design: Innovations in manufacturing techniques and component design are expected to result in smaller and lighter CVT units, leading to enhanced vehicle packaging.

CVT’s Role in Automotive Evolution

CVTs are playing an increasingly important role in the evolution of automotive technology. Their adaptability and efficiency make them suitable for various vehicle types and powertrains. The integration of CVTs with other vehicle systems, such as electric motors and advanced driver-assistance systems, is transforming the driving experience.

Impact of Electric Vehicles on CVT Design

The increasing adoption of electric vehicles (EVs) is impacting CVT design significantly. The characteristics of electric powertrains necessitate specific CVT design considerations. For example, the need for smooth torque delivery and rapid acceleration necessitates advanced control strategies for electric-CVT integration.

Potential Integration with Other Vehicle Systems

The integration of CVTs with other vehicle systems, such as ADAS, is a significant trend. This integration could lead to more sophisticated driving experiences and improved safety features. For example, a CVT system that dynamically adjusts its characteristics based on ADAS input could contribute to improved safety during lane changes or emergency maneuvers.

CVT and Environmental Impact: CVT Transmission

Continuously evolving automotive technologies are pushing the boundaries of vehicle performance and efficiency. One such technology, the continuously variable transmission (CVT), has garnered attention for its potential to positively impact environmental factors. This section delves into the environmental footprint of CVT transmissions, examining its impact on emissions, fuel economy, noise pollution, and energy efficiency.The environmental impact of any vehicle technology is multifaceted, considering factors like manufacturing processes, operational efficiency, and the overall lifecycle of the product.

A thorough evaluation of CVT transmissions in this context provides a more complete picture of their role in sustainable transportation.

Environmental Footprint of CVT Transmissions

CVTs, unlike traditional transmissions, offer a continuously variable gear ratio. This feature, while enhancing performance, also impacts the environmental performance of the vehicle. The reduced number of gears in a CVT translates to a simplified mechanical design. However, the complex hydraulic and electronic components required for a CVT’s operation do add to the manufacturing footprint and energy consumption.

Potential for Emission Reduction

The optimized power delivery inherent in CVT design can contribute to improved fuel economy, which, in turn, reduces tailpipe emissions. By providing a wider range of gear ratios, CVTs can maintain an optimal engine speed for different driving conditions. This precise control of engine speed is often associated with reduced engine load, leading to lower fuel consumption and, consequently, reduced emissions.

For example, certain CVT designs have demonstrated a reduction in NOx emissions compared to traditional automatic transmissions.

Impact on Fuel Economy and Overall Environmental Performance

The improved fuel efficiency associated with CVTs directly contributes to a reduced carbon footprint. Studies have shown that CVTs can improve fuel economy by up to 10% in certain driving scenarios, relative to traditional automatic transmissions. This improved fuel economy directly translates into reduced greenhouse gas emissions and a lower overall environmental impact.

Impact on Noise Pollution

The smoother and more continuous power delivery of a CVT often results in less engine noise and vibration compared to traditional transmissions. This is because the engine operates at a more consistent speed range, minimizing the jarring shifts and the noise associated with traditional gear changes.

CVT transmissions, while offering a smooth driving experience, can sometimes impact monthly car payments. Factors like the specific model and features of the car, as well as current market conditions, can all affect the final amount of monthly car payments. Ultimately, the CVT transmission itself is a key component to consider when looking at the overall car financing.

Potential for Improved Energy Efficiency

CVTs are capable of achieving higher energy efficiency by optimizing the engine’s operation across a wider range of speeds and loads. The smooth, seamless power delivery can minimize energy loss associated with traditional transmission shifts. In addition, advanced CVT designs often incorporate features like regenerative braking, which captures kinetic energy and converts it back into electrical energy, further enhancing overall energy efficiency.

CVT in Different Regions

Continuously evolving automotive landscapes across various regions exhibit diverse adoption rates for Continuously Variable Transmission (CVT) technology. Factors such as local preferences, government regulations, and the prevailing automotive industry structure all play a significant role in shaping CVT market penetration. Understanding these nuances is crucial for assessing future trends and potential for CVT growth in different markets.The adoption of CVT technology varies considerably across different automotive markets.

Factors such as consumer preferences, government regulations, and the structure of the local automotive industry all play a vital role in determining the level of CVT adoption in each region. The availability of suitable alternatives and the overall economic climate of a region are also important considerations.

CVT Adoption Rates Across Automotive Markets

Analyzing the adoption rate of CVT technology in different automotive markets requires a nuanced understanding of regional preferences and industry dynamics. The success of CVT hinges on factors such as consumer acceptance, the availability of suitable alternatives, and the economic climate of the region. Examining market trends offers insights into the future trajectory of CVT adoption.

| Automotive Market | CVT Adoption Rate (Approximate Percentage) | Reasons for Adoption/Lack of Adoption |

|---|---|---|

| Japan | High (over 50%) | Strong consumer preference for smooth performance and fuel efficiency, along with a well-established automotive industry adept at integrating CVT technology. |

| Europe | Moderate (20-40%) | Consumer preferences often favor traditional automatic transmissions, and regulatory standards concerning fuel efficiency and emissions play a significant role in the adoption of different technologies. |

| North America | Moderate (20-40%) | Similar to Europe, consumer preferences are a major factor. The availability of alternatives and the preference for powerful engine options also influence the market share of CVT. |

| China | Increasing (10-30%) | Rapid growth in the automotive industry and a focus on fuel efficiency are driving the adoption of CVT. |

| South America | Low (below 10%) | A combination of factors, including consumer preferences, the availability of suitable alternatives, and the overall economic climate, influences the low adoption rate. |

Comparison of CVT Use in Different Automotive Markets

The usage of CVT technology differs substantially across various automotive markets. For instance, in Japan, CVT is a popular choice due to consumer preference for a seamless driving experience. In contrast, some European markets show a lower adoption rate, possibly due to consumer preference for traditional automatic transmissions. This variance highlights the diverse considerations impacting CVT adoption in different regions.

Understanding the specifics of each market is essential for evaluating the long-term potential of CVT technology.

Market Trends Related to CVT

Emerging market trends suggest a gradual increase in CVT adoption globally. This is fueled by a growing emphasis on fuel efficiency and a desire for smooth performance. However, the pace of adoption varies across regions. In countries with a strong emphasis on fuel efficiency, such as Japan and parts of Asia, CVT is more readily accepted. In regions with more established preferences for other transmission types, adoption remains more modest.

Reasons for CVT Popularity or Lack Thereof

The popularity or lack of CVT adoption in different regions is rooted in a multitude of factors. These include consumer preferences, the availability of suitable alternatives, economic factors, and regulatory standards. Consumer preferences play a crucial role, as different regions may have distinct driving styles and preferences for vehicle characteristics. The presence of readily available alternatives, such as dual-clutch transmissions or traditional automatics, can also influence the choice of transmission type.

Government regulations, such as fuel efficiency standards, also play a significant role in driving the adoption of CVT technology. In regions with stricter fuel economy requirements, CVT’s efficiency advantages become a compelling factor.

Final Wrap-Up

In conclusion, CVT transmission represents a significant advancement in automotive engineering. While offering unique advantages, such as enhanced fuel efficiency and smooth operation, CVT transmissions also present specific maintenance and design considerations. Understanding these nuances is crucial for maximizing the benefits and mitigating the drawbacks of this technology. The future of CVT transmissions is bright, promising further advancements and integration into a wider range of vehicles.

FAQ Overview

What are the common problems associated with CVT transmissions?

Some common problems include slipping, noise, and vibration, potentially caused by worn components or fluid issues. Proper maintenance, including regular fluid changes, can mitigate these problems.

How does CVT transmission impact fuel efficiency?

CVT transmissions often improve fuel efficiency due to their ability to optimize power delivery across a wider range of engine speeds. However, factors like driving style and vehicle weight influence the overall outcome.

What are the different types of CVT designs?

Several types of CVT designs exist, each with its own characteristics and applications. These designs vary in complexity, component materials, and overall performance.

What are the key design parameters for a robust and reliable CVT?

Key parameters include component strength, durability, friction characteristics, and fluid management systems. These aspects directly impact the longevity and reliability of the transmission.