Car rims are more than just decorative accessories; they play a crucial role in a vehicle’s aesthetics and performance. From alloy to steel, various materials and designs offer different advantages. Understanding the types, sizes, and performance considerations of car rims is essential for informed choices.

This comprehensive guide delves into the world of car rims, exploring everything from design and aesthetics to performance, materials, and maintenance. We’ll cover a wide range of topics, including different rim types, their applications, and the factors that affect pricing. Whether you’re a seasoned car enthusiast or just starting your journey, this resource provides a wealth of information to help you make the right choices for your vehicle.

Introduction to Car Rims

Car rims, also known as wheels, are crucial components of a vehicle, playing a significant role in both its aesthetic appeal and performance characteristics. They act as a critical connection between the vehicle and the road, supporting the weight of the car and ensuring a smooth ride. Properly designed and maintained rims contribute to better handling, braking, and fuel efficiency.The design and construction of car rims vary widely, reflecting the diverse needs and preferences of car owners.

Different types of rims, materials, and specifications cater to specific performance requirements and visual preferences, allowing for customization and enhancing the overall appeal of a vehicle. This section will provide a comprehensive overview of car rims, encompassing their types, materials, and common specifications.

Types of Car Rims

Different types of rims cater to various performance and aesthetic requirements. Steel rims are a cost-effective and readily available option, providing adequate structural support for basic vehicles. Alloy rims, typically made of aluminum alloys, offer a lighter weight, enhanced durability, and a broader range of design options, making them a popular choice for performance-oriented vehicles.

Materials Used in Car Rim Manufacturing

The material used in rim construction significantly impacts the rim’s performance and durability. Steel rims, primarily composed of carbon steel, offer excellent strength and stability. Aluminum alloy rims, commonly featuring a combination of aluminum, magnesium, and other metals, provide a lighter weight compared to steel, improving handling and fuel efficiency. The choice of material directly influences the rim’s overall weight, strength, and cost.

Common Sizes and Specifications of Car Rims

Rim size is a critical specification, influencing the vehicle’s performance and appearance. The standard rim size typically includes the diameter and width of the rim. For example, a 17-inch rim with a 7-inch width is a common specification for many passenger vehicles. Specific sizes are determined by the manufacturer, considering the vehicle’s design and performance requirements. A detailed table of common rim sizes and specifications is presented below:

| Rim Size (inches) | Diameter (inches) | Width (inches) | Common Applications |

|---|---|---|---|

| 15 | 15 | 6.5 | Economy cars, smaller SUVs |

| 16 | 16 | 7 | Mid-size cars, some SUVs |

| 17 | 17 | 7.5 | Popular for many passenger cars and some SUVs |

| 18 | 18 | 8 | Performance-oriented vehicles, some luxury models |

| 19 | 19 | 8.5 | High-performance cars, luxury vehicles |

Design and Aesthetics

Car rims are more than just functional components; they significantly impact a vehicle’s overall aesthetic appeal. Their design, size, and finish contribute substantially to the car’s visual identity and style, influencing the perception of its performance and prestige. Choosing the right rims can elevate a vehicle’s appearance from ordinary to extraordinary.The visual impact of rims is multifaceted, encompassing factors like the rim’s shape, the number of spokes, the material, and the finish.

These features interact to create a visual language that speaks volumes about the car’s intended image and the driver’s personal style.

Rim Design Variations

Different rim designs cater to diverse aesthetic preferences. Understanding these variations helps in selecting rims that complement the car’s style. The variety of designs is a testament to the creative potential in automotive accessory design.

- Five-Spoke Rims: A classic and popular design, five-spoke rims offer a balanced aesthetic. Their symmetrical structure often exudes a sense of robustness and traditional style, aligning well with various vehicle body styles.

- Multi-Spoke Rims: These rims feature more than five spokes, creating a more intricate and visually dynamic appearance. The number of spokes and their design can range from subtle and refined to bold and aggressive, catering to different tastes. They often convey a sense of modernity and dynamism.

- Single-Piece Rims: Single-piece rims are forged or cast as a single unit, resulting in a seamless and lightweight design. Their robust construction often lends itself to a more performance-oriented aesthetic, suggesting strength and precision.

Popular Rim Styles and Their Associations

Specific rim designs are often associated with particular vehicle styles and market segments. The choice of design can influence the car’s overall image.

- Sporty/Aggressive Styles: Often characterized by large, multi-spoke rims with a polished or matte black finish, these rims project an image of power and performance. Examples include rims with 5-spoke or 10-spoke designs with aggressive profiles.

- Luxury/Premium Styles: These rims often feature intricate designs, such as multi-spoke rims with polished or chrome finishes, to enhance the vehicle’s premium image. They emphasize elegance and sophistication, often seen in high-end sedans and SUVs.

- Classic/Retro Styles: Classic designs, like five-spoke rims with a polished or brushed finish, bring a sense of timeless appeal. These rims often evoke a vintage or classic look, frequently found on vehicles styled to reflect a specific era.

Rim Styles and Visual Examples

The table below showcases various rim styles and their associated visual characteristics. The visual representations illustrate the range of aesthetics achievable through rim design.

| Rim Style | Image Description |

|---|---|

| Five-Spoke | A five-spoke rim, typically symmetrical and robust-looking. Imagine a classic, understated design with five spokes radiating outwards from the center. |

| Multi-Spoke (10-Spoke) | A multi-spoke rim (e.g., 10 spokes) showcasing a more intricate and dynamic design. Visualize a design with more spokes, potentially more pronounced than a five-spoke design, with more pronounced curves or angles. |

| Single-Piece | A single-piece rim, characterized by a seamless and lightweight design. Imagine a smooth, uniform rim with no visible joints or seams, possibly with a polished or brushed finish. |

| Sporty/Aggressive | Large, multi-spoke rims with a polished or matte black finish. Picture rims with significant size and depth, possibly showcasing an aggressive, pronounced design with a black finish. |

| Luxury/Premium | Intricate multi-spoke rims with polished or chrome finishes. Imagine intricate designs and a luxurious appearance with polished or chrome highlights. |

| Classic/Retro | Five-spoke rims with a polished or brushed finish. Visualize a classic design, perhaps with a polished or brushed finish, reminiscent of older car styles. |

Performance Considerations

Car rims, often overlooked, play a crucial role in a vehicle’s overall performance. Beyond aesthetics, the choice of rims significantly impacts handling, braking efficiency, and even fuel economy. Understanding these effects allows drivers to make informed decisions aligning rim selection with desired performance characteristics.Rim selection impacts a vehicle’s dynamics in several key areas. The width, weight, and offset of the rim, along with the corresponding tire selection, directly influence how the vehicle interacts with the road.

Careful consideration of these factors leads to enhanced performance and a more enjoyable driving experience.

Rim Width and Tire Performance

Tire performance is intrinsically linked to rim width. Wider rims accommodate wider tires, which generally improve stability and cornering ability. Wider tires distribute the contact patch more evenly across the road surface, leading to increased grip and reduced tendency to understeer or oversteer. This enhanced grip translates to better handling in various conditions, from spirited cornering to navigating slippery surfaces.

However, wider rims and tires can sometimes increase rolling resistance, potentially affecting fuel economy.

Rim Weight and Vehicle Dynamics

Rim weight significantly affects vehicle dynamics. Lighter rims reduce unsprung weight, which contributes to quicker steering response and improved handling. Lighter rims also lessen the load on the suspension, which can translate into a more comfortable ride and reduced wear and tear on the vehicle’s components. Conversely, heavier rims can result in slower steering response, potentially compromising handling performance, especially at higher speeds.

A good example of this is the difference in handling between a sports car with lightweight rims compared to a heavier, more rugged SUV with heavier rims.

Rim Offset and Vehicle Appearance and Handling

Rim offset, the distance between the mounting surface of the rim and the center of the wheel hub, affects both the visual appearance of the vehicle and its handling characteristics. A positive offset results in a more prominent outward protrusion of the wheel, often favored for its aesthetic appeal. Conversely, a negative offset recedes the wheel inward, giving a more tucked-in look.

Offset choice influences the overall balance and stance of the vehicle. Additionally, offset impacts the amount of tire that’s visible outside the wheel well, influencing the vehicle’s aesthetic. For example, a lowered vehicle with negative offset rims will give the appearance of the car sitting lower to the ground, but it may also affect the tire’s ability to clear suspension components.

Materials and Manufacturing

The materials used in car rim production significantly impact their performance, aesthetics, and lifespan. Choosing the right material involves balancing factors like strength, durability, weight, and cost. Different manufacturing processes also contribute to the final product’s characteristics and quality. This section will delve into the properties of common materials and the various manufacturing methods employed in rim creation.

Material Properties

Rim materials must withstand the stresses and forces encountered during vehicle operation. Aluminum alloys are a popular choice due to their high strength-to-weight ratio. Steel rims, while heavier, offer exceptional strength and durability. Other materials, such as magnesium alloys, are gaining traction for their lightweight properties.

Aluminum Alloys

Aluminum alloys are widely used in car rims due to their desirable combination of lightness and strength. This allows for better handling and fuel efficiency. Various grades of aluminum alloys exist, each possessing specific characteristics. 6061-T6, for example, is a common alloy known for its high strength and corrosion resistance. The specific alloy selected often depends on the intended use and the desired balance between weight and strength.

Steel Rims

Steel rims, despite being heavier, offer unparalleled strength and durability. They are a cost-effective option for vehicles where extreme performance isn’t a priority. Their high tensile strength makes them ideal for applications where the rim needs to withstand significant impacts. However, steel’s heavier weight contributes to a slightly reduced ride comfort and fuel efficiency.

Magnesium Alloys

Magnesium alloys, with their exceptionally low density, are becoming increasingly popular for high-performance vehicles. This material’s light weight contributes to enhanced handling and fuel economy. However, magnesium alloys are often more susceptible to corrosion than aluminum or steel alloys. Their higher cost also restricts their widespread adoption.

Comparison Table

| Material | Advantages | Disadvantages |

|---|---|---|

| Aluminum Alloys | High strength-to-weight ratio, good corrosion resistance, relatively low cost | Potentially lower impact resistance compared to steel, can be more expensive than steel in some cases |

| Steel | Exceptional strength and durability, cost-effective | Heavier, lower strength-to-weight ratio compared to aluminum, susceptible to rust |

| Magnesium Alloys | Extremely low density, excellent strength-to-weight ratio, superior handling and fuel economy | Higher susceptibility to corrosion, higher cost |

Manufacturing Processes

Different manufacturing techniques result in varying rim designs and characteristics. Casting, forging, and machining are common methods used in the production of car rims. Each method affects the final product’s quality and properties.

Casting

Casting involves pouring molten metal into a mold to create the desired shape. This method is often used for creating complex designs, but it can lead to inconsistencies in material density.

Forging

Forging involves shaping metal by hammering or pressing it. This method results in a denser and more uniform material, which contributes to increased strength and durability.

Machining

Machining uses tools to precisely shape and refine the rim’s surface and dimensions. This process is crucial for achieving intricate designs and precise tolerances.

Quality Control

Rigorous quality control measures are essential in rim manufacturing. This ensures that rims meet the required standards for strength, durability, and safety. Testing procedures like impact resistance and stress testing are common.

Installation and Maintenance

Proper installation and consistent maintenance are crucial for the longevity and performance of your car rims. Neglecting these aspects can lead to premature wear, damage, and even safety hazards. This section details the essential steps and procedures for a smooth installation process and the importance of regular maintenance.

Rim Installation Procedure

A meticulous installation process is vital to ensure proper fit and functionality. Incorrect installation can lead to premature damage to the rims and potentially compromise the safety of the vehicle. The following steps Artikel the standard procedure for mounting rims:

- Preparation: Thoroughly inspect the rims for any damage. Ensure the wheel studs are in good condition and the correct size. Check the wheel bolts for tightness and the presence of any wear or corrosion. Verify the tire size compatibility with the rims.

- Mounting the Tire: Carefully position the tire onto the rim, aligning the bead seating correctly. Use the appropriate mounting tools and procedures to ensure proper tire seating. Use a tire mounting machine for optimal results. Ensure the tire is centered on the rim.

- Balancing: After mounting the tire, it is imperative to balance the wheel and tire assembly. This process distributes the weight evenly across the wheel to minimize vibrations. See the next section for detailed instructions.

- Bolting: Use the proper torque specifications to tighten the wheel bolts. Tighten them sequentially and evenly to avoid any misalignment. Refer to your vehicle’s manual for the exact torque specifications.

- Final Inspection: After installation, thoroughly inspect the assembly for any signs of misalignment or damage. Ensure the wheel bolts are properly tightened. Drive the vehicle on a smooth surface to ensure there are no vibrations or noises.

Rim and Tire Balancing

Proper balancing is essential for a smooth and comfortable driving experience. Imbalances can cause vibrations and premature tire wear, leading to a potentially dangerous driving experience. The process of balancing involves adjusting the weight distribution on the rim and tire assembly.

- Identifying the Imbalance: Using a balancing machine, the machine will identify the location and magnitude of the imbalance. This is typically done by spinning the wheel and detecting any vibrations.

- Adding Weights: Small weights are strategically placed on the opposite side of the detected imbalance to counter the uneven weight distribution. These weights are usually made of lead or another suitable material. The specific location and amount of weights are determined by the balancing machine.

- Verification: The wheel and tire assembly are re-spun on the balancing machine to verify that the imbalance has been corrected. This process is repeated until the machine indicates the wheel and tire are balanced.

Regular Rim Inspections and Maintenance

Regular inspection and maintenance are crucial for preventing potential problems. Prompt attention to any issues can save you from costly repairs. The frequency of inspections should be determined by your driving conditions and habits.

- Visual Inspection: Regularly inspect your rims for any signs of damage, such as dents, cracks, or corrosion. Look for any unusual wear or deformation on the wheel bolts.

- Cleaning and Lubrication: Clean the rims regularly to remove dirt and debris. Apply a lubricant to the wheel studs and bolts to prevent rust and corrosion.

- Checking for Damage: Look for any signs of damage such as cracks, dents, or loose bolts. Assess the condition of the wheel studs and bolts.

- Tire Pressure Monitoring: Ensure proper tire pressure as specified by your vehicle’s manual. This is critical for optimal performance and handling. Low tire pressure can damage the rims over time.

Common Rim Issues and Solutions

Various issues can affect your rims, ranging from minor problems to significant damage. Addressing these issues promptly can prevent further damage.

| Issue | Solution |

|---|---|

| Corrosion | Thoroughly clean and lubricate the rims and wheel bolts. Consider using rust-inhibiting products. |

| Bent Rims | Seek professional repair or replacement, as bent rims can lead to handling issues and potential safety risks. |

| Loose Bolts | Tighten the bolts to the specified torque. If loose bolts persist, consult a professional mechanic. |

| Damage from Impacts | Professional repair or replacement is typically necessary for significant damage. |

Rim Sizes and Specifications

Rim size selection is crucial for both the aesthetic appeal and performance of a vehicle. Choosing the right rim size ensures proper tire fitment, optimal handling, and a visually appealing appearance. Understanding rim dimensions and their impact on a vehicle is essential for informed decision-making.

Common Rim Sizes and Tire Recommendations

Proper tire selection is paramount for vehicle safety and performance. Matching the correct tire size to the rim size is critical. The following table Artikels some common rim sizes and recommended tire sizes. Note that these are guidelines, and specific recommendations may vary based on vehicle make, model, and intended use.

| Rim Size (inches) | Recommended Tire Size (e.g., width/aspect ratio/diameter) | Notes |

|---|---|---|

| 17 | 225/45R17 | A popular size for many vehicles; provides a balance of handling and ride comfort. |

| 18 | 235/40R18 or 245/40R18 | Offers improved handling and a sportier appearance. |

| 19 | 245/35R19 or 255/35R19 | Common choice for sporty vehicles; provides a more aggressive look and enhanced handling. |

| 20 | 255/30R20 or 275/30R20 | Common for luxury vehicles or high-performance models; provides a larger, more dramatic look. |

Rim Dimensions: Diameter, Width, and Offset

Rim dimensions significantly impact vehicle performance and appearance. Understanding these dimensions is crucial for selecting the right rims for a vehicle.

Diameter: Refers to the overall size of the rim, typically measured in inches. A larger diameter generally improves ride comfort, but can affect the vehicle’s handling and ground clearance.

Width: Measures the rim’s width, also in inches. Wider rims offer better stability and handling, but may require specific tires for proper fitment.

Offset: Indicates the position of the wheel mounting surface relative to the center of the rim. Offset affects the position of the tire on the vehicle, influencing the vehicle’s handling and appearance. A positive offset pushes the tire outward, while a negative offset pushes the tire inward.

Significance of Correct Rim Size

Correct rim size is vital for vehicle safety and performance. Mismatched sizes can lead to several issues.

- Safety Concerns: Incorrect rim sizes can cause uneven tire wear, potentially leading to tire failure and accidents. Mismatched sizes can also affect the vehicle’s handling characteristics, increasing the risk of loss of control.

- Performance Issues: Inaccurate rim sizes can lead to a compromised ride quality, reduced handling, and diminished braking performance. This can result in decreased vehicle stability and responsiveness, which can be critical in emergency situations.

Visual Impact of Rim Sizes

Rim size significantly impacts a vehicle’s visual appearance. The visual impact depends on the vehicle’s overall style and the specific rim design.

- Visual Impression: Larger rims can enhance the vehicle’s sporty appearance, while smaller rims can provide a more understated or elegant look.

- Proportion and Aesthetics: The size of the rims needs to be proportional to the vehicle’s overall body style and dimensions. A mismatched size can negatively affect the vehicle’s aesthetic appeal.

Rim Types and Applications

Rim selection is crucial for optimizing vehicle performance and aesthetics. Different vehicle types demand specific rim characteristics, ensuring a balance between visual appeal, structural integrity, and functional suitability. Understanding these types and their applications is vital for informed choices.

Rim Types for Performance Cars

Performance cars, often prioritizing handling and acceleration, benefit from lightweight rims. These typically feature a low profile and intricate designs to enhance aerodynamic efficiency and reduce unsprung weight. For example, forged aluminum rims are commonly employed due to their strength and light weight, which improves acceleration and braking responsiveness. These rims often showcase unique designs and finishes, reflecting the performance-oriented nature of the vehicle.

The specific choice of alloy and design depends on the specific performance goals and budget of the vehicle owner.

Rim Types for SUVs

SUVs, emphasizing capability and practicality, require rims that can handle heavier loads and rough terrain. These rims typically feature a robust construction and wider widths, often incorporating stronger studs or bolts for enhanced load-bearing capacity. For instance, steel rims, though often perceived as basic, provide exceptional durability and are a suitable choice for vehicles frequently traversing challenging off-road conditions.

They are generally more resistant to damage from impacts and wear compared to lighter alloy rims. Often, the design emphasizes a balanced combination of strength and aesthetic appeal, suitable for both on-road and off-road driving.

Rim Compatibility

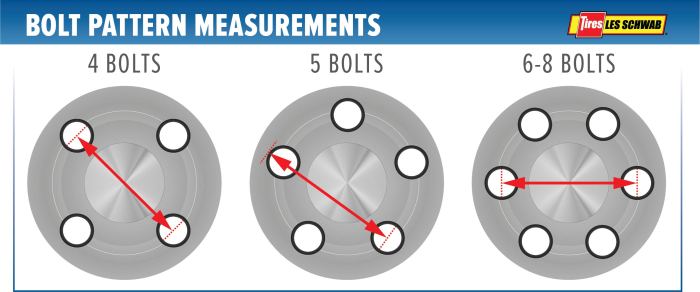

Rim compatibility is paramount. Incorrect rim sizing or incompatible mounting hardware can lead to safety hazards and premature wear. Manufacturers provide precise specifications regarding the correct rim dimensions, including width, offset, and bolt pattern. Adhering to these specifications is essential to maintain proper wheel alignment, handling, and vehicle stability. For instance, using a rim that is too narrow or has an improper offset can result in uneven tire wear or damage to the suspension.

Rim Categorization by Vehicle Type

| Vehicle Type | Rim Type | Intended Use | Key Features |

|---|---|---|---|

| Performance Cars | Forged Aluminum | Enhanced handling, acceleration, and braking | Lightweight, intricate designs, high strength |

| SUVs | Steel, Aluminum | Load capacity, off-road capability | Robust construction, wider widths, strong studs/bolts |

| Sedans | Aluminum | Balanced performance and aesthetics | Various designs and finishes, moderate weight |

| Trucks | Steel | Heavy load-carrying | High durability, robust construction |

Budget and Price Considerations

The price of car rims can vary significantly, influenced by a multitude of factors. Understanding these factors allows consumers to make informed decisions and find rims that fit their budget without compromising desired quality and performance. This section explores the key elements impacting rim pricing, compares costs across different types and materials, and highlights budget-friendly options that still deliver.Choosing car rims involves a delicate balance between aesthetics, performance, and budget.

Consumers need to weigh the value proposition of each option, carefully evaluating how the features and quality align with their specific needs and financial constraints. This crucial step helps avoid costly mistakes and ensures a rewarding investment in their vehicle’s appearance and functionality.

Factors Affecting Rim Price

Several factors contribute to the cost of car rims. Material quality, manufacturing processes, design complexity, and brand reputation all play significant roles. Rims crafted from premium alloys or featuring intricate designs will typically command a higher price compared to simpler, more basic options. Furthermore, well-established brands often have higher prices due to their reputation for quality and reliability.

Comparison of Rim Types and Materials

Different rim types and materials exhibit variations in cost. Alloy rims, a popular choice for their strength and lightweight nature, generally fall within a mid-range price bracket. Steel rims, being more basic and less expensive, are often used as a cost-effective option. Forged rims, known for their superior strength and performance, typically have a higher price point due to their specialized manufacturing process.

High-end, custom-designed rims, often featuring unique designs and intricate finishes, carry the highest price tags.

Affordable Rim Options

While seeking high-quality rims within a budget requires careful consideration, it’s achievable. Several options exist to find suitable rims without sacrificing quality. Look for reputable brands with a proven track record of quality control. Consider less complex designs, opting for standard or slightly modified styles. Explore used or refurbished rims, often available at significantly reduced prices, provided they meet the necessary quality standards.

Rim Price Comparison Table

| Rim Type | Material | Typical Price Range | Key Features |

|---|---|---|---|

| Alloy | Aluminum Alloy | $150-$500+ per rim | Lightweight, durable, good strength-to-weight ratio, aesthetically pleasing. |

| Steel | Steel | $50-$200 per rim | Basic, affordable, suitable for vehicles with lower performance needs. |

| Forged | Aluminum Alloy (forged) | $250-$1000+ per rim | Exceptional strength and durability, precise design, often used in high-performance vehicles. |

| Custom | Aluminum Alloy (or other) | $500-$5000+ per rim | Unique designs, intricate finishes, often with specific aesthetic preferences. |

Note: Prices are approximate and can vary depending on the specific rim size, design, and brand.

Rim Accessories and Customization

Beyond the fundamental design and performance characteristics, car rims benefit significantly from a range of accessories and customization options. These additions can significantly enhance the visual appeal and even subtly influence the handling characteristics of a vehicle. From subtle aesthetic enhancements to performance-oriented upgrades, the options are extensive and allow owners to tailor their rims to their specific needs and preferences.Accessories and customization options extend far beyond the basic rim itself, transforming a simple wheel into a personalized statement.

This process can involve both superficial aesthetic upgrades and potentially more intricate modifications that impact handling and performance. The key lies in carefully selecting accessories that complement the rim style and enhance the overall aesthetic without compromising functionality.

Rim Accessories

A variety of accessories enhance the visual appeal and practical functionality of rims. These include center caps, which cover the center hole of the wheel, and lug nuts, which secure the wheel to the vehicle’s hub. Center caps typically match the design theme of the rim, while lug nuts are often chosen for their visual appeal, strength, and material properties.

- Center Caps: These decorative pieces cover the central opening of the wheel. They are often designed to complement the overall aesthetic of the rim, with options available in various materials, colors, and designs. A classic example involves a simple, metallic cap that harmonizes with the overall design of a sporty alloy wheel, whereas a more elaborate, intricate design might be chosen for a high-end, custom-built rim.

- Lug Nuts: These crucial components secure the wheel to the vehicle’s hub. Beyond their functional role, lug nuts can also be customized to match the aesthetics of the rims. Available in different materials (e.g., aluminum, steel), finishes (e.g., polished, matte), and styles, they provide a noticeable visual enhancement. High-quality lug nuts are essential for maintaining the integrity of the wheel-hub assembly and contribute to the vehicle’s overall appearance.

Customization Options

Various customization options allow for personalized expression. Painting and powder coating are popular methods for altering the appearance of rims. Painting offers a wide spectrum of colors, while powder coating provides a durable, long-lasting finish. Both methods can transform the look of a rim, creating a unique aesthetic that complements the vehicle’s style.

- Painting: Painting offers a vast array of color options, enabling customization to match specific vehicle themes or personal preferences. However, painted rims require more frequent maintenance and may not be as durable as powder-coated options. The color selection is virtually unlimited, allowing for a wide range of aesthetic outcomes. A custom-painted rim might be a deep, rich blue to enhance the sporty appearance of a vehicle or a matte black finish to create a stealthy look.

- Powder Coating: Powder coating provides a durable, long-lasting finish. It offers a range of colors and finishes, with the added benefit of resistance to corrosion and scratches. Powder coating is a superior choice for those seeking a more durable and long-lasting finish, and it can also be utilized to enhance the visual appeal of the rim with various finishes, such as gloss or matte.

Matching Accessories to Rim Style

Careful consideration is crucial when choosing accessories to complement the rim style. The design and aesthetic of the rim dictate the best choices for center caps and lug nuts. A simple, clean rim design might benefit from understated accessories, while a more elaborate rim design might accept more elaborate choices. Careful selection of accessories ensures the aesthetic harmony of the entire wheel assembly.

- Harmony is Key: A well-designed rim benefits from accessories that harmonize with its design language. A simple, clean rim design often looks best with minimalist accessories, whereas a more elaborate rim might be enhanced by more elaborate and bold accessories. This visual cohesion is paramount in enhancing the overall appeal of the vehicle.

Customization Project Examples

Several examples illustrate the impact of rim customization. A matte black powder-coated rim with matching black center caps and lug nuts can dramatically enhance the sporty look of a vehicle. Conversely, a polished aluminum rim with chrome center caps and lug nuts can create a sophisticated and refined aesthetic. The choice directly impacts the overall visual character of the vehicle.

- Matte Black Transformation: A matte black powder-coated rim with matching black center caps and lug nuts instantly adds a sporty, stealthy aesthetic. This is a popular choice for vehicles aiming for a contemporary, aggressive look.

- Polished Aluminum Sophistication: A polished aluminum rim with chrome center caps and lug nuts presents a sophisticated and refined aesthetic. This is often preferred for vehicles seeking a more upscale or classic appearance.

Safety and Legal Considerations

Choosing the right car rims isn’t just about aesthetics; it’s a critical safety and legal decision. Properly fitted rims, adhering to safety standards and regulations, are essential for vehicle stability, performance, and compliance with the law. Ignoring these aspects can lead to serious consequences.Ensuring your rims meet safety standards and legal regulations is paramount. This section delves into the importance of compliance, potential risks, and the legal ramifications of using non-compliant rims.

Importance of Safety Standards

Rims are a crucial component of a vehicle’s safety system. They directly affect the vehicle’s handling, stability, and ability to withstand stress during braking and cornering. Rims that do not meet safety standards can compromise these functions. Using rims that don’t meet industry standards could lead to reduced braking performance, increased risk of accidents, and potential damage to the vehicle.

Legal Regulations Regarding Car Rims

Various jurisdictions have specific regulations regarding car rims. These regulations often cover aspects like rim size, load capacity, and the use of specific types of rims for different vehicle models. Violation of these regulations can result in penalties and legal repercussions.

Potential Risks of Using Unsafe or Improperly Fitted Rims

Using unsafe or improperly fitted rims presents several potential risks. These risks include reduced handling, increased risk of wheel separation, and potential damage to the vehicle’s suspension system. For instance, rims that are too small or too large for the vehicle can cause vibrations, affecting the steering and braking response. Mismatched rims can also lead to uneven tire wear, reduced fuel efficiency, and premature tire failure.

Additionally, poorly fitted rims can cause the vehicle to become unstable at high speeds or during sharp maneuvers, increasing the risk of accidents.

Consequences of Using Non-Compliant Rims, Car rims

Using non-compliant rims can result in various penalties, ranging from fines to vehicle impoundment. These consequences can vary significantly based on the specific regulations in place in a particular jurisdiction. Moreover, depending on the severity of the non-compliance, insurance companies might not cover damages resulting from accidents involving non-compliant rims. Examples include the risk of voiding warranties on the vehicle, or encountering difficulties in getting insurance coverage in the future.

A significant consequence is the potential for serious injuries or fatalities if the rims fail during critical conditions like high-speed driving or harsh braking.

Rim Trends and Future Developments

Rim design is constantly evolving, driven by advancements in materials, manufacturing techniques, and the ever-changing demands of automotive aesthetics and performance. This dynamic environment fosters innovation and pushes the boundaries of what’s possible in wheel design. Understanding current trends and anticipated future developments is crucial for staying informed about the latest innovations and their potential impacts.The current landscape of rim design is characterized by a blend of traditional styles and cutting-edge approaches.

Modern consumers are seeking wheels that offer not only visual appeal but also enhanced performance characteristics. This multifaceted demand fuels ongoing research and development, shaping the future direction of rim technology.

Current Trends in Rim Design

Current trends in rim design emphasize lightweight construction, aerodynamic enhancements, and intricate design patterns. Manufacturers are exploring innovative materials and production methods to achieve these objectives. For instance, forged aluminum rims are becoming increasingly popular due to their exceptional strength-to-weight ratio, which translates to improved handling and fuel efficiency. Furthermore, the integration of advanced design software and 3D printing technologies enables intricate, artistic wheel designs that were previously impossible to produce.

Future Developments in Rim Materials and Manufacturing

The quest for lighter, stronger, and more durable rim materials is ongoing. Carbon fiber composites are poised to play a significant role in future rim production, potentially offering even greater weight reductions than current aluminum alloys. This could result in significant performance improvements, including enhanced handling and fuel efficiency. Additive manufacturing (3D printing) will likely become more prevalent in the manufacturing process.

This technology allows for complex geometries and personalized designs, opening up new possibilities for rim aesthetics and function. Researchers are also exploring the use of advanced polymers and alloys with enhanced strength and corrosion resistance.

Impact of New Technologies on Rim Design and Performance

New technologies are expected to profoundly influence rim design and performance. For example, the integration of sensors into rims can provide real-time data on tire pressure, temperature, and even road conditions. This data can be used to improve driver safety and vehicle performance. Further development of smart materials, such as self-healing polymers, could revolutionize rim maintenance, potentially eliminating the need for frequent repairs.

This development could translate to improved safety and reliability. The integration of advanced materials with lightweight design principles will enable lighter, stronger, and more aesthetically pleasing rims.

Emerging Trends in Car Rim Customization

Customization is a key element in the current automotive market. Rim customization extends beyond simply choosing different colors or styles. Consumers are increasingly seeking unique and personalized designs. This trend is being driven by the accessibility of design software and 3D printing technologies, allowing individuals to create and customize their rims with intricate and personalized designs. The rise of online marketplaces and direct-to-consumer sales channels facilitates the customization process, putting greater control in the hands of the consumer.

Furthermore, the integration of advanced technologies like embedded lighting and interactive design elements are expanding the horizons of rim customization.

Last Recap: Car Rims

In conclusion, choosing the right car rims involves careful consideration of aesthetics, performance, and budget. Understanding the different types, materials, and sizes available is crucial. This guide has provided a comprehensive overview of car rims, from their design and manufacturing to installation and maintenance. By considering these factors, you can select rims that not only enhance your vehicle’s appearance but also improve its performance and safety.

FAQs

What are the common issues associated with car rims and their solutions?

Common issues include bent rims, damaged welds, and loose lug nuts. Solutions range from professional repair to replacement, depending on the severity of the damage.

What is the importance of rim offset on vehicle appearance and handling?

Rim offset affects how the wheel sits on the vehicle’s suspension. Proper offset is essential for a balanced appearance and optimal handling characteristics.

How do car rims affect vehicle performance?

Rim width and weight directly impact tire performance, handling, and braking. Choosing the right rim type and size is crucial for optimal performance.

What are the different types of car rims available?

Common types include alloy and steel rims, each with its own set of characteristics and applications.